Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Developing human machine interfaces using smart display modules part 1.

16 November 2017

Summary :

One of the mast important task of developing an interactive electronic device is the definition of the HumanMachine Interface (HMI)The chosen technology should fulfill all required controlling tasks, and in the meantime needs to be easy to implement and operate, affordably priced, rugged, usable in harsh environment and last but not leaststylish, modern in appearance. Further requirement is being able to provide an easy way of facelift in case of implementing new features or changing outlook. In this paper we introduce a possible solution, using DLOGIC’s Smart Display Modules to achieve fast time to market when designing state of the art HMI solution.

The designers of electronics devices equipped with traditional TFT touch displays know very well how long it takes to discover and get rid of the hidden hardware and software bugs. If one may choose DLOGIC’s robust, nicely designed, reliable, affordable and ready to use Smart Display Modules, the development time will be much shorter, therefore the time to market of the finished product can be minimized. This paper will introduce the features of this product, the development theory and would review the steps to get to a project.

HumanMachine Interface (HMI)

The human machine interface is responsible to provide interaction between the user and the intelligent electronic equipment. Most of the times this is a two ways communication, as users give commands and in return they expect some status information about the machine. In modern designs customers

are not satisfied any longer to interact using push buttons, mechanical switches or keyboards, or getting feedback through status lamps, seven segment or simple monochrome LCD displays, or via acoustics ways. Today it is basic expectation to have high resolution, even sunlight readable color TFT touch displays, with rugged, robust, but slim and professional industrial design, in special applications even with higher IP protection or using special material such as stainless steel in the housing or thick protective glass over the touch panel. There are many solutions to meet such expectations, however interfacing the graphics controller, to fine tune the touch panel behavior all require complicated hardware design experience and takes long time to implement. Facelift or extending the solution with extra features would also take manpower and engineering hours to involve, just changing TFT size, introducing new function buttons or just change the look and feel can cause lot of unforeseen trouble. A possible solution for these problems can be to use a single board computer just for limited HMI functions, which usually has on board a direct RGB interface connector for adapting the TFT panel, free serial port for the touch panel. In this case the HMI design requires nearly only software related investment. If a PC is available in the finished product, maybe an industrial open frame monitor could be used via VGA or HDMI connection. Even in these cases we still have to coop with some driver problems, hardware matching issues as well as solving issues with IP protection, physical protection and mechanical docking. All of these tasks may delay the product to be marketed offering advantages to the competitors, that are using more advanced technologies for the HMI design.

How can we implement a simple, state of the art, modern and stylish, scalable HMI solution then? The right technological answer is to use the so-called Smart Display Modules.

Smart Displaymodules

The Smart Display Modules (SD modules or SDM) are compact mainly ARM Cortex microcontroller-based panel PCs, which hold integrated excellent quality TFT display with touch panel and suitable to serve as programmable intelligent interactive control panels. They offer all functions that are required by any Human Machine Interface, next to their perfect visual properties they are featured by many of industry standard communication interfaces just like USB, RS232/485. Ethernet, CAN bus, General Purpose I/O ports, PWM outputs. When using such an SDM simple functions like user authentication (simple password based or RF ID, retina scanning or finger print detection), information and instruction distribution (video streaming) can be transferred from central PC to save resources. In simple applications, like intelligent coffee machines, or other white goods, it may be enough to use an SDM for all control functions, but for more complicated devices they are only used as an extension to the central control unit offering only human machine interfacing. This is due to the limited capabilities of the ARM controller in comparison with a full featured industrial PC.

Using DLOGIC display modules offer significant advantages when designing new touch-controlled electronics devices as the design of the HMI stays simple and scalable by requiring pure software development. No need of deep knowledge of the used hardware elements, no need to design circuits or interfacing sub systems, the designers can count of the competence of DLOGIC and save their resources to the finished product development. The ready HMI hardware platform offers shorter time-to-market of the end-product, lower development costs, junior programmers can program all interactive functions, while senior developers can concentrate on device feature development. These high-quality displays are suitable for indoor and outdoor installation in different versions, there are front- and rear mount types with aluminum or stainless-steel housing. The rugged vandal proof versions are equipped with 4 mm safety glass. There are many options available for meeting challenges of different environmental circumstances, such as customizable IP protection level on the backside or at the connectors of the module. All spare parts and sub systems are guaranteed to work on industrial temperature range and selected carefully to provide long time market availability. Based on this DLOGIC can guarantee at least 7 years of availability of each SD modules in the program.

DLOGIC SDMfamily

The DLOGIC Smart Display Modules are in fact ARM Cortex microcontroller based mini panel PCs, running Linux operating system, that are designed mainly for industrial displaying applications. The flexible design makes them extremely suitable for humanmachine- interfaces, supporting wide operational temperature range and having high immunity of harsh environmental impacts. The modules incorporate perfect display features, the industry leading projective capacitive touch technology in combination with the ARM based microcontroller unit providing graphical subsystem (GPU) and a series of industrial interface protocols such as galvanic separated CAN-bus, RS-485, MDB, RS-232, I2C, SPI, USB, Ethernet, MicroSD, PWM, S/PDIF and GPIOs. The modules can be supplied by 9-38V DC voltage.

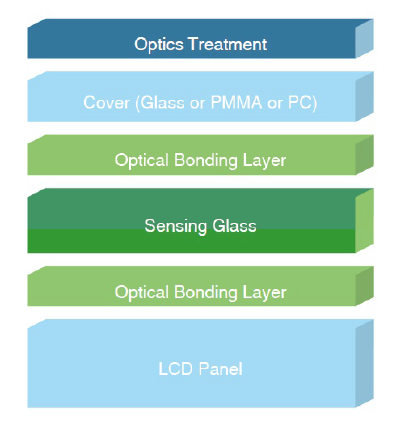

The DLOGIC SD modules are available in 4.3”, 5”, 7”, 9”, 10.1 ”, 12.1 ” and 15” sizes, with wide viewing angle and min. 550 cd/m2 of backlight brightness for good horizontal or vertical readability. The layers of the display are glued together by using optical bonding technology in order to avoid internal air gaps between the layers, which could cause reflection, that decreases readability especially in high ambient light conditions (outdoor, sunlight).

The liquid glue fills up the possible air gaps, providing better optical features as well as mechanical strength for the complete installation. It also improves the resistance against dust, moisture and dirt, increasing the protection level of the display module itself.

On top of the touch panel there is a tempered glass cover lens hardened over 8H, while the industry standard requires only 6H for vandal proof design. This safety glass is also attached to the touch panel by using optical bonding, which enables flat and smooth front surface arrangement without glare and reflection. The standard delivery program contains various kind of displays by means of housing material or build form in order to provide maximum flexibility for customer design in various environmental conditions.

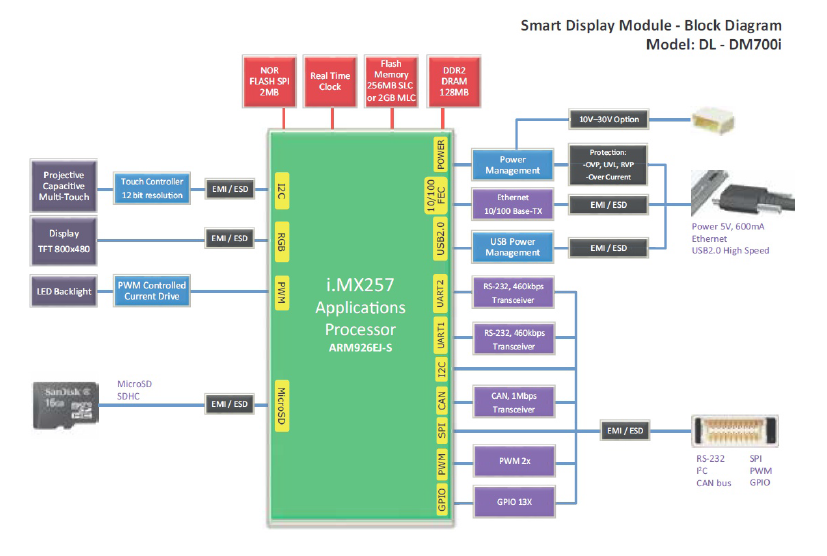

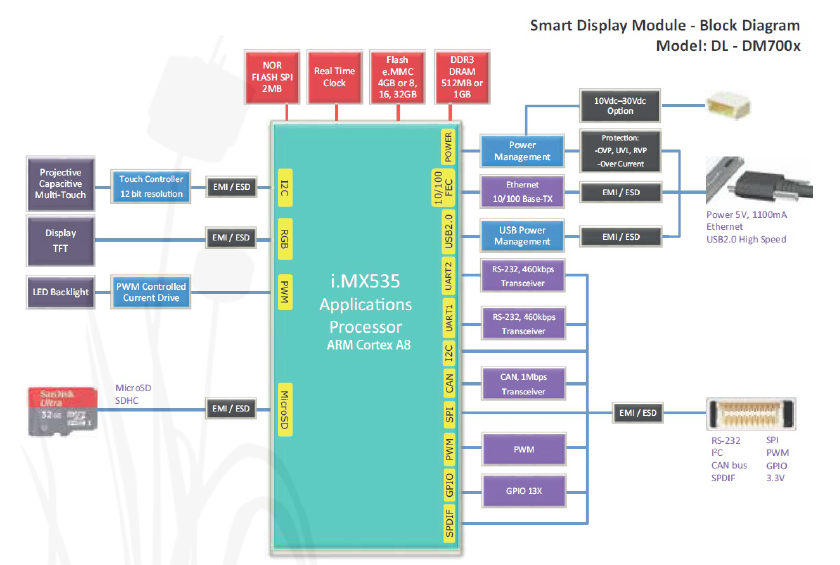

There are front and rear mount types, water-, dust-, moisture-, shock- and vibration proof versions available with aluminum or - especially for laboratory or food processing applications - stainless steel housings. In case of special customer requirements there is a possibility of customization. The Smart Display Modules are organized around two processor platforms, the “x” series features Freescale Arm Cortex A8, iMX535 , while the „i” series has Freescale Arm 9, iMX257 applications processor. The cheaper “I” versions are perfect for applications with lower resource requirements, where the key selling point is price, while the “x” version has a built in graphic processor offering 3D rendering and video streaming. As the new versions of Qt cross compiler development system do not support the software rendering any more when in graphics mode, one may have difficulties when not choosing this enhanced type “x” family. The „x” family is the right choice for those HMI solutions where static graphics design should be extended with modern and complex graphics objects and solutions such as 3D effects or real time video streaming.

The programmable display module

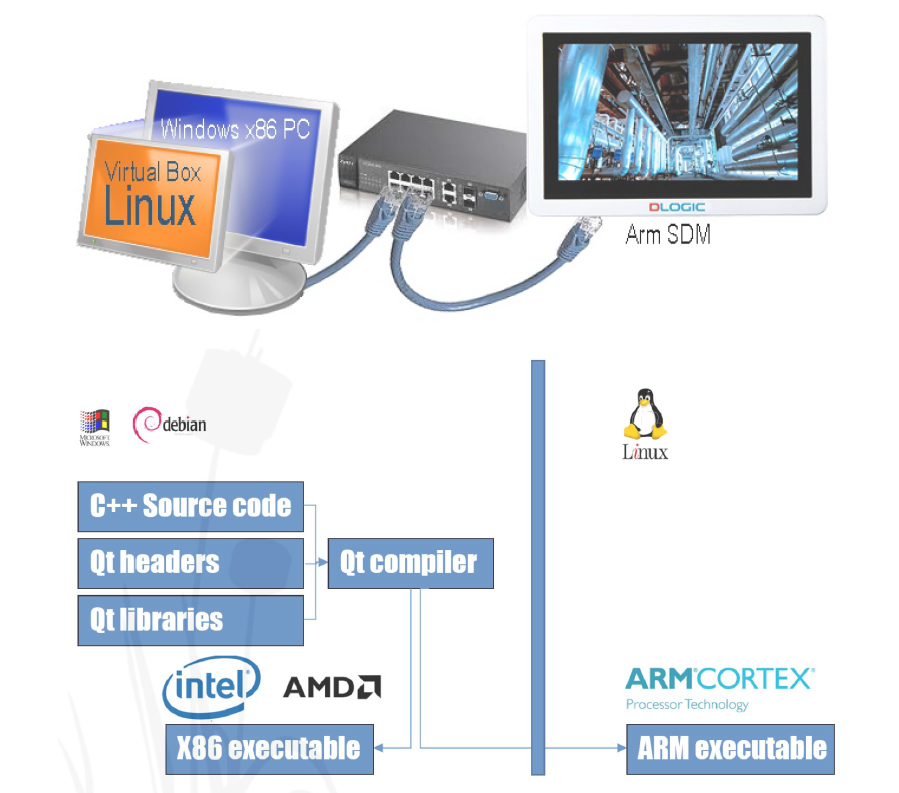

As written before, the HMI design can be made by software development. The board support package installed on every SD modules and given as a virtual machine image contains all preconfigured software tools that are required for the fast application development. The user can define the look and feel of the interface, can choose predefined widgets such as radiobuttons, checkboxes, buttons, sliders, images, icons. One can then write event handlers for these elements and can control the SDM’s embedded hardware ports such as general purpose I/O ports, serial interfaces, PWM outputs and so on. In the next article of tis series we are going to introduce the way of handling these hardware components, and show some software examples to control electromagnetic or solid state relays through GPIO ports of the SDM, to control the speed of a fan or to change the intensity of the display’s backlight usin pulse with modulation. Before starting the programming, it is however a must to understand the technology that provides a platform independent software development, the so called “cross-compiling” theory, that makes it possible to develop and debug the HMI program on an Intel x86 based personal computer and then export the executable to ARM Cortex platform and run it on the Smart Display Module. In order to start development, it is strongly recommended to all future users of DLOGIC Smart Display Modules to purchase a development kit for the chosen display type. This kit contains the display module itself as well as mounting aid, connection kit (cables) and also a pc board containing physical connection to the interface ports such as GPIOs, serial ports, CAN bus etc. The package price contains also software support provided by DLOGIC authorized software engineering team.

The SDM arrives with a preinstalled Debian Linux distribution, the development environment however arrives as a virtual machine disk image file from the manufacturer to be installed to users’ desktop PCs. This package is fully set up for the purchased display module type and ready to be used after the few minutes process of importing the virtual machine. It is recommended to use Oracle’s VirtualBox on user’s desktop PC’s Windows environment, where the imported virtual machine will run a Debian Linux distribution very similar to the one on the SDM. This Debian and the pre-installed QT graphical IDE offers perfect development environment to set up a HMI. The Debian Linux open source operating systems is known to be one of the most stable and reliable Linux distributions, running in high numbers of computers and servers all over the world. There are many known and popular software packages available for the software developers. DLOGIC’s modules are preinstalled with all required tools and drivers and 1 00% checked before delivery. Qt IDE provides a perfect design tool for a modern, state-of-the-art, stylish HMI design.

The essence of the cross-compiling theory is, that the developer uses a computer for writing and debugging the HMI software, and later deploys the executable for a different platform that the compiler itself is running on. The x86 based developer PC and the SDM are physically connected to the same Ethernet network, and the TCP/IP communication between the two systems is possible either by using a terminal emulator of through SFTP protocol.

The x86 (Windows) PC has a virtual computer installed on it, running Debian Linux and Qt IDE is set up as well. In 1 37 QT it is possible to set up the type of the executable file, whether the resulted binary file is to run on x86 or ARM platform. The deployment is done automatically through SFTP. The hardware of the SDM can be accessed through a special file system, therefore the even handler software written for the used widgets should perform file accessing tasks in order to operate the GPIO ports or reading from and writing to serial peripherals. Writing well defined values to the /sys/ filesystem makes GPIO ports change their behavior (direction, high or low value etc.) or PWM can be set up by adjusting period times and duty cycle. By applying the predefined widgets and writing event handler C++ code it is possible to realize control functionality, and setting up the graphical appearance, one can define a modern HMI design. In the next article we provide software examples for the controls.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2017/7 | Elektronet : elektronikai informatikai szakfolyóirat, 2017. (26. évf.) 7. sz. 29-32. old. |

| 2 | TechStory M2M | Okoskijelzők használata |

| 3 | Hungarian version | Okoskijelzők használata - ember–gép interfész (HMI) megvalósítása DLOGIC modulokkal 1. rész |

| 4 | Jövő Gyára 2017/4 | 2017. (3.évf.) 4.sz. 34-36.old. |

| 5 | New Technology online | Okoskijelzők használata – ember–gép interfész (HMI) megvalósítása DLOGIC modulokkal |

| 6 | New Technology 2018/1 | Okoskijelzők használata – ember–gép interfész (HMI) megvalósítása DLOGIC modulokkal |