Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

DC-DC switching power supply regulators from New Japan Radio

23 April 2018

![]()

Summary :

DC/DC converters are essential elements of today’s battery driven consumer electronics devices, which often contain subsystems with own level of required supply voltage. Mainly the lack of the available space forces designers not to use different batteries but use voltage converters to produce various voltages available, sometimes even higher than the battery voltage, and often provide regulated output, which is important as the battery voltage decreases by losing the stored power. DCDC converters, which convert the input voltage to a lower level are called stepdown or buck converters, the ones producing higher voltage than the battery voltage are called step up or boost converters.

General overview of voltage regulation

To produce different voltage levels out of the battery voltage could be done on several ways, like using resistor-based voltage dividers, or linear regulators, but these solutions can only provide lower level of voltages and the efficiency is low, as - if the voltage drop is high and the current is large-, the excess power will be lost by dissipating remarkable heat. Better to use today switching mode DC/DC converters, which temporarily storing energy in magnetic or electric storage components and releasing this energy to result different voltage level on the output. The efficiency will be remarkable higher resulting better battery lifetime at the end.

Step Down / Buck converters

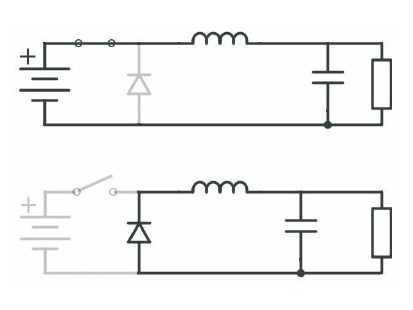

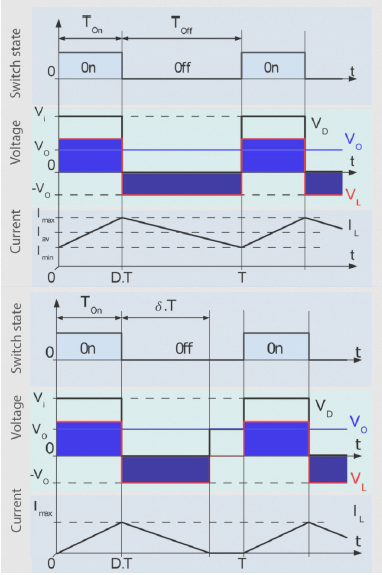

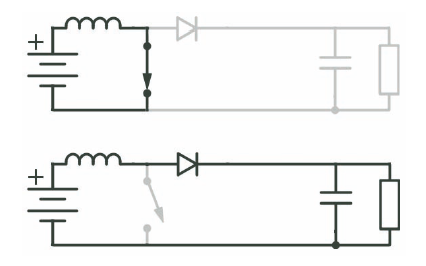

Those switching more DC/DC converters, that are characterized by lower Vout than Vin are generally called step down or buck converters. Their working principle is based on the ideal circuit shown in figure 1 . The switch on the circuit represents the element that is used for connecting and disconnecting the circuit and the battery, which is in a MOSFET or an IGBT component. The inductor is used for storing the energy, by building up its magnetic field right after the battery is connected to the circuit. During charging, the inductor would produce a voltage drop that is reducing the voltage of the load. If the switch opens before the charging is complete, the output voltage remains always less than the battery voltage. At this moment the flyback diode switches on, and provides a closed circuit, which could then discharge the energy stored in the magnetic field. As long as the switch off period is shorter than the discharge time of the inductor, the voltage of the load is always higher than zero, as the inductor pumps energy and supports current flowing through the load. The average voltage on the output is always lower than the input supply voltage. The parallel capacitor is placed for smoothing the ripple voltage resulted by fluctuation of voltage in each cycles of switching. Operating mode of the DC/DC step down converter is continuous mode, when the current of the inductor cannot decrease to zero. If the energy stored in the inductor is not large enough to supply the current in the whole switch off state of the cycle, the current will be zero for the part of the cycle. This operation mode is called discontinuous mode.

The figures show the differences:

Synchronous switching

There is an enhanced version of buck regulators, which is inherited from the conventional stepdown converter circuitry. In this type the fly-back diode is replaced by a complementary-out driver operated second switching element (lower switch). As the switch element (MOSFET/IGBT) has remarkable lower RDSon value, the power loss resulted by the voltage drop of the fly-back diode used in the conventional solution will be reduced. In both cases the power loss is dependent on the duty cycle. The other advantage of this solution is that the converter is bidirectional. This solution is however a compromise between higher cost (more expensive elements) a better performance.

Controlmodes

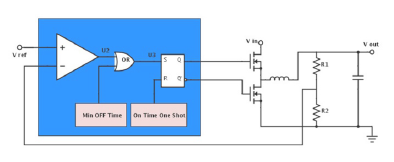

Most common control mode of the switching more voltage regulators is the fixed frequency PWM (Pulse Width Modulation) control, where a PWM control circuit provides the complementary switching. The other well-known control mode is the hysteretic voltage control. In this solution no oscillator is needed, therefore no issues with the frequency compensation. The system is using a comparator, where upper and lower threshold values are set up. The voltage ripple on the output connected as a kind of feedback to the comparator, and when the ripple voltage exceeds the high reference value, the high side switch turns off, the low side switch turns on, the output voltage falls down, therefore ripple will be also reducing. Constant on time (COT) control regulators need no oscillator, and also use the output ripple voltage to initiate switching ON, but this case the high side switch stays switched ON for a fixed duration. Advantage of such a construction is the higher efficiency on light load as well as the fast-transient response. However, for these solutions the output capacitor should have a high ESR to produce ripple voltage drop high enough, which results in noise sensitivity on the output.

Power converter selfprotection

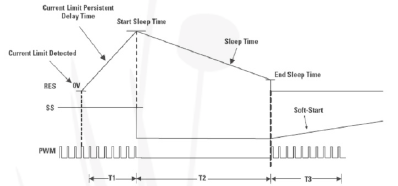

In order to improve the power converter reliability, the producers apply several kinds of self-protections. In addition to conventional non- recoverable protection modes (fuses, circuit breakers) and resettable protection (PolySwitches, Multifuses etc.), DC/DC converters are equipped with self-recoverable protection features. Cycle-by-Cycle current limiting protection detects the overload condition and limits the duty cycle. In this case the high side switch is ON just for a short time, therefore the buck diode is carrying the load current for long time resulting thermal management problem. Unless the diode and the heatsink is oversized this condition delivers to a lifetime issue. The hiccup mode current-limiting scheme can overcome the disadvantages. Once an overload situation is detected the converter is switched off and forced into sleep mode for a defined time. At the end of the sleep time, a restart attempt is made and if the overload condition persists, the process is repeated. In constant overload situation the converter experiences a series of bursts followed by sleep time, hence the name ‘hiccup’ mode. The sleep time reduces the average current and allows the converter to cool down.

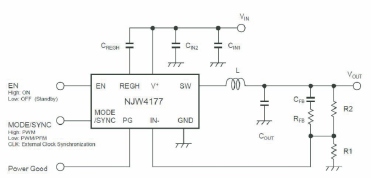

New Japan Radio’s NJW4177 is a synchronous switching regulator IC for buck converter with 40V, 2A MOSFET, with 350/450 kHz frequency oscillating, wide input voltage (3.6-40V), hiccup mode overcurrent protection and standby function. The built-in phase compensation, the internally fixed soft start features together with the current mode control, which enables to use low ESR Output Capacitors (MLCC), the NJW41 50 can realize downsizing of applications with a few external parts. It makes the IC suitable for power supply circuit of Car Accessory, Office Automation Equipment and Industrial Instruments. The efficiency of general pulse width modulation-based voltage regulators decreases in light load conditions, that may result unforeseen problems of quick discharge in battery powered applications.

The NJW4177 can select PFM (pulse frequency modulation) mode to ensure higher efficiency, due to the minimized FET switching losses. It is suitable for power supply circuit of microprocessor, DSP and automotive accessories that need fast transient response, and where it is important to keep the leakage current small by using an enable input, and in sleep mode to have the standby current less than 5µA.

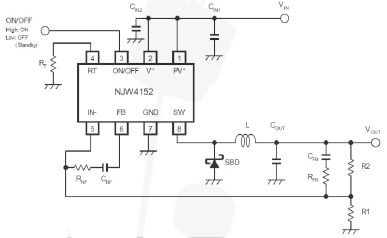

Another other solution is the NJW4152 buck converter with 40V/650mA or 40V/1A MOSFET within wide input range from 4.6V to 40V, that adopts current mode control - sensing and feedbacking the current of the coil - with just a few additional spare parts around. The switching frequency can be set between 300 kHz to 1MHz, and when selecting the highest values, it is enough to use a smaller sized inductivity. The output voltage can be set between 0.8V to Vin-1V. The buck converter is suitable for power supply circuit of car accessories, office-automation equipment and industrial tools.

Step Up / Boost converters

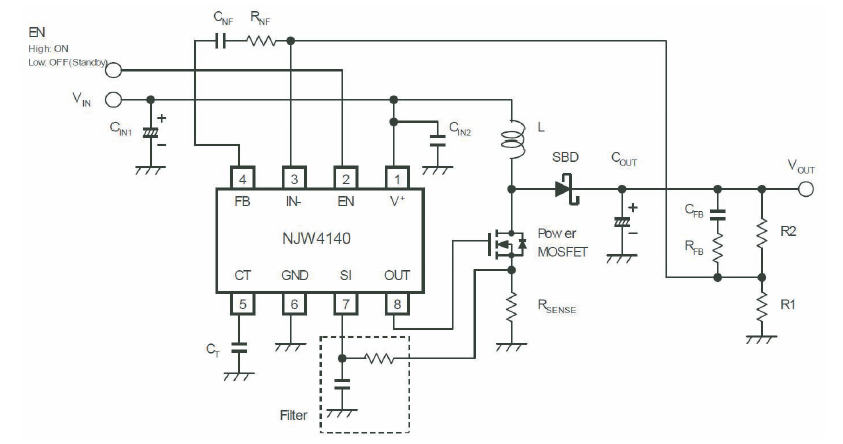

Those switching more DC/DC converters, that are characterized by higher output voltage than supply voltage is called step up or boost converters. The ideal circuit diagram presents the working principle:

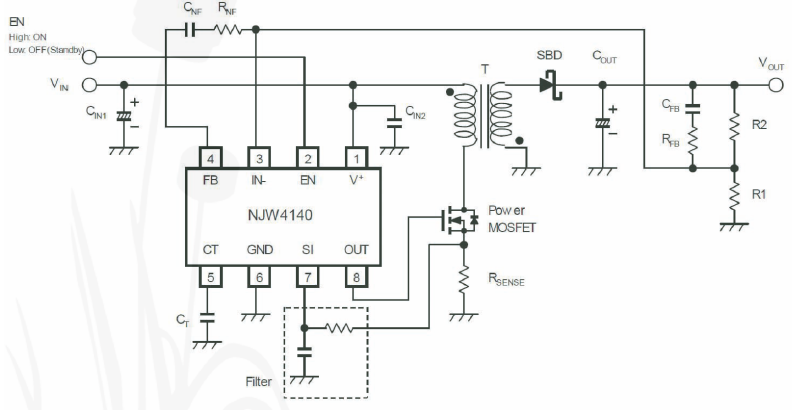

When the switch is “on”, the inductor starts to charge, while load voltage is zero. Once the switch is open the energy stored in the magnetic field is starting to support current flowing through the load, and the two sources in series are causing higher voltage to charge the capacitor through the diode. When the switch is again off, the diode prevents the capacitor to discharge. If the switching is fast enough, the inductor will not discharge completely before the next charging cycle, therefore the output voltage is always higher than the voltage of the power source alone. One of the popular MOSFET drive switching boost/fly-back converter solutions is the New Japan Radio NJW41 40 IC. The PWM switching frequency can be selected in the range of 40 kHz to 1MHz. With its highly efficient built-in N tunnel MOSFET drive circuit it is especially suitable for high current applications and operates on a wide input voltage range of 4.0V to 35V. It is suitable for boost or fly-back applications such as powering of car accessory, office automation equipment and industrial instrument. The NJW4040 offers over current protection, UVLO under voltage lockout function and also has a standby mode. The sample circuit diagrams are shown on the figures.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Hungarian version | DC-DC kapcsolóüzemű feszültség átalakítók az NJRC kínálatából |

| 2 | TechStory M2M | DC/DC kapcsolóüzemű feszültségátalakítók működése |

| 3 | Jövő Gyára 2018/2 | 2018. 2.sz. 33-34.o. |

| 4 | Magyar Elektronika online | DC/DC kapcsolóüzemű feszültségátalakítók a New Japan Radio Corporation-től |

| 5 | Magyar Elektronika 2019/4 | 2019. 4.sz. 25-26.o. |