Ian Doyle - ProTek Devices, Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Overvoltage protection with PROTEK TVS diodes in automotive electronics

ELEKTRONET 8 February 2016

Summary :

Automotive electronics is maybe the area of the automotive industry, which has developed the most in the last decades. It’s been almost 50 busy years since the first engine control unit (ECU) was placed in the car, and today there are dozens of microprocessor controlled systems in each vehicle. Car manufacturers keep on designing more and more IC based systems to provide enhanced features, which also challenge circuit protection manufacturers to follow the trends by introducing proper solutions to decrease servicing and warranty costs. Therefore, proper circuit protection is an important factor of any automotive design process.

Systems need circuit protection in cars

Car electronics systems are used to control engine behavior, as well as some safety systems like brakes, airbags, collision avoidance and parking assist. Sometimes these safety systems are obligatory to be used by law, like direct tyre pressure monitoring systems (TPMS) are now required on all new cars sold in the EU, and E-call systems will also be necessary to be integrated soon. Of course more and more systems provide driving comfort, like telematics, navigation or heated / cooled seats. The above mentioned equipments often include USB ports, Ethernet ports, CAN Bus lines, LINBus, antenna, display interfaces, power systems, fuel injection management systems, and many more. Electrical transients may be present are critical risk to damaging these systems. Damages caused by electrical transients should be avoided by proper circuit protection to decrease servicing and warranty costs.

Electrical transients in automotive electronics

To standardize the tests of checking automotive systems’ immunity to electrical fast transients, the Automotive Electronics Council (AEC) provides a discrete semiconductor qualification standard for automotive applications. The AEC-Q1 01 standard refers to automotive circuit protection standards.

Different transient are involved like:

- Electrostatic discharge [ESD] test based on human body or machine model.

- Transient created by unclamped inductive switching.

- Load dump pulse, which is generated when a load to which a generator is delivering current is abruptly disconnected.

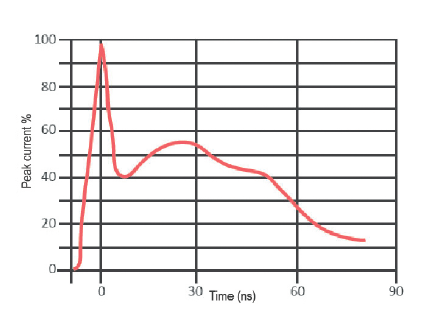

Voltage transients can be categorized into three types: ESD, Surge and Load dump. Electrostatic discharge (ESD) occurs, when a charge is exchanged between two objects of different charge potential, mainly between human beings and metal objects. Usually a visible spark is generated as a result of breaking down the isolating dielectric between the objects. This is featured by 2-1 5 kV (level 1 -4) air discharge voltage, relative small energy and short (ns) duration.

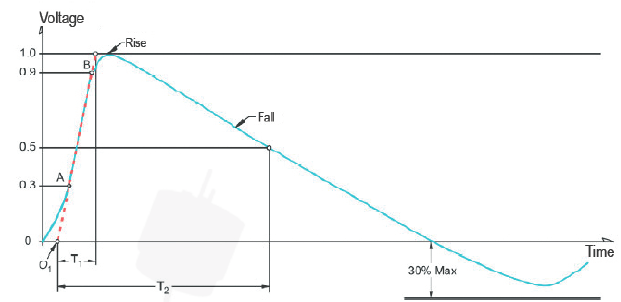

The surge is a different kind of transient overvoltage event, that is characterized by longer (microsecond) duration, large energy. A surge voltage is mainly caused by a transient of an inductive switching.

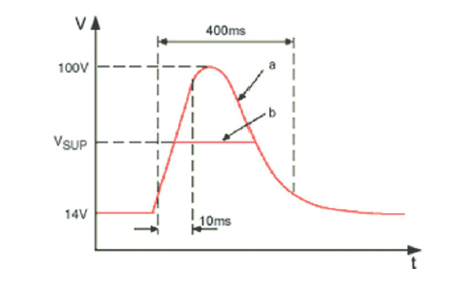

oad dump is a long duration, usually millisecond long overvoltage event, usually caused by switching off a load from an inductive supply, like battery is disconnected from charging circuit, while charging.

The millisecond long rise is followed by a slow decay, resulting a high energy transient. In automotive electronics, this applies to disconnecting a battery while it is being charged by the alternator. Signal levels can be as high as 174 V and may take up to 400 ms to decay. In the table we have summarized all the overvoltage events (and their properties), that should be considered when designing appropriate overvoltage protection. Some of these threats are really critical for the electronics systems, therefore is the requirement for overvoltage protection solutions.

| Transients in automotive electronics | ||||

|---|---|---|---|---|

| Duration | Cause | Voltage amplitude | Energy level | Frequency of occurrence |

| 200ms | Load Dump (Disconnection of battery while at high charging) | < 125V | > 10J | Infrequent |

| Steady State | Failed Voltage Regulator | 18V | Infrequent | |

| < 320μs | Inductive Load Switching | 80V to 300V | < 1J | Often |

| 200ms | Alternator Field Decay | -100V to -40V | < 1J | Each Turn-Off |

| 90ms | Ignition Pulse, Battery Disconnected | < 75V | < 0.5J | < 500Hz Infrequent |

| 1ms | Harness Coupling | < 200V | < 1J | Often |

| < 60ns | Electrostatic Discharge | < 15kV | < 10mJ | Infrequent |

Companies like ProTek Devices have long provided qualified standards-based circuit protection components that are widely used to protect popular automotive systems. The automotive product line largely consists of a modern comprehensive family of transient voltage suppressor arrays (TVS array). The seeds of these matrix systems are the Silicon Avalanche Junction TVS (transient voltage suppressor) diodes.

TVS devices

TVS diodes contain a P/N junction similar to a Zener diode, having however a lager cross section, proportional to the surge power handling rating of the device. In order to handle longer duration transients, engineers can choose higher sizes with better heat dissipation. The devices are available from chip size to large module units. Although rated at lower surge current levels than MOVs, the voltage as well as the power capabilities can be increased by using more devices series or parallel. TVS diodes can handle today high surge currents, for example Protek’s 2700SM78CA can handle 1 8 kA, a 1 2V rated 600W device has a 8/20 μs surge capacity of 1 40 A. Failure mechanism of TVS diode is a short circuit. They have fast response time as a result of the silicone technology, because the response is proportional to the electron’s speed.

As the protection device should be invisible at normal operating conditions even on higher frequencies, sometimes ultra low capacitance has to be achieved (pF). GBLC08CLC has a line capacitance of 0.4 pF. TVS devices can be used in unidirectional configurations for DC lines as well as in bidirectional organization for AC applications. Unlike MOVs, which display initially perfect leakage behavior, but later performance degrades with every surge exposure, TVS has no aging effect, the leakage current characteristic shows no degradation over time. It has a response time in the sub nanosecond range as well as low clamping factor (~1 .33). PROTEK’s automotive product line of ultra-low capacitance transient voltage suppressor arrays (TVS array) cover just about any automotive circuit protection needs such us in infotainment, lighting, drive-train, safety and body systems.

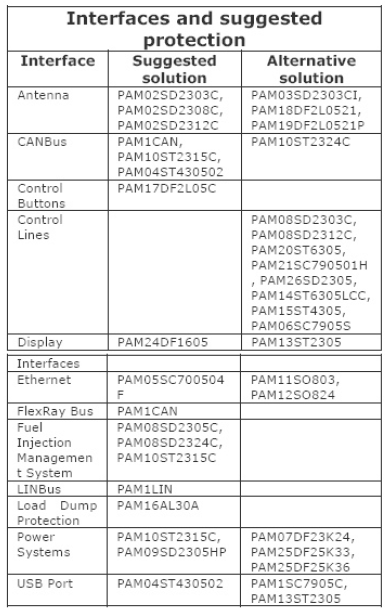

On the next sections we will show a few application examples used in automotive designs.

Systems need circuit protection in cars CAN and LIN Bus protection

The cars today have dozens of electronic control units (ECU) for different subsystems, some are very complicated, like the engine control unit. Others are used for transmission, airbags, ABS, tempomat, controlling windows, doors, mirror adjustment or driving power steering, battery recharging system etc. Some of them are independent subsystems, like the car’s audio system, but communications with other systems are still essential. Controlling commands actuators and also it needs data from sensors. When all subsystems had its own independent wiring, the weight, volume − thus the cost of cabling − would raise.

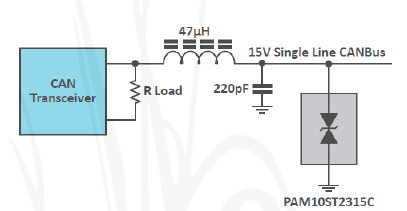

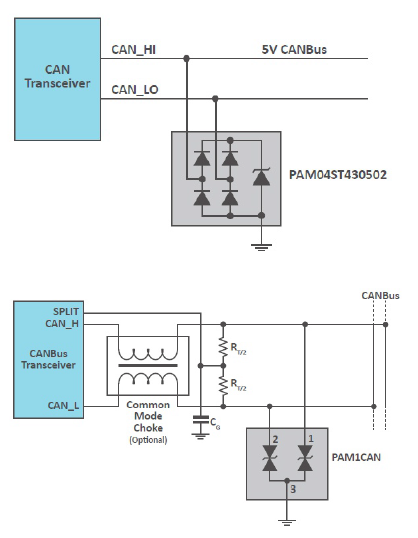

The CAN (Controlled Area Network) standard was developed to solve this problem, as it is a multi-master serial bus standard for connecting Electronic Control Units [ECUs] − also known as nodes − using a single 1 20 r twisted pair physical wiring. The nodes can be simple I/O devices up to an embedded computer with a CAN interface and its own software. The node may also be a gateway allowing a standard computer to communicate over a USB or Ethernet port to the devices on a CAN network. Due to the different connections and the complexity of the system, it is essential to provide overvoltage protection for the bus itself, which can be done with one of Protek’s CAN devices shown on the figures.

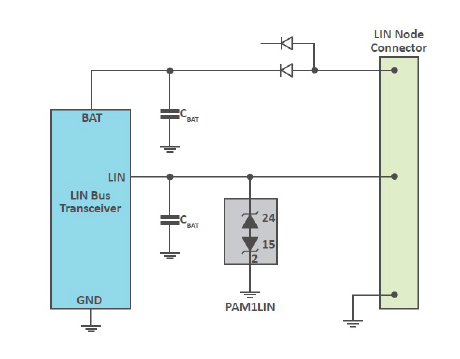

As CAN bus maybe too expensive to implement for all the intelligent components of the automobile, LIN (Local Interconnect Network) is a cheap complementary solution. The LIN bus is an inexpensive serial broadcast communications protocol, which effectively supports master-slave remote communication within the car’s network usually up to 1 6 slave devices, such as mechatronic nodes. It is mend to extend the existing CAN network. As being part of the car’s network efficient overvoltage protection is a must.

Protection of power systems

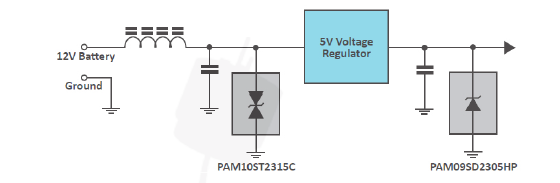

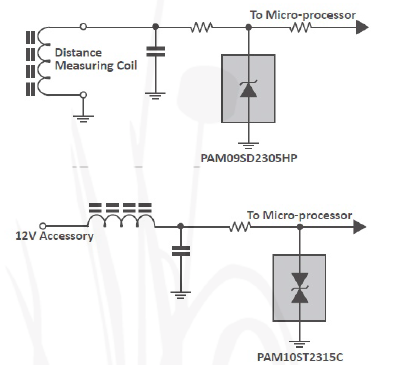

The battery driven car electronics power systems can be protected against ESD, tertiary lightning & switching transients by using the PAM devices, like for distance measuring, any other 1 2V devices, and voltage regulators as well.

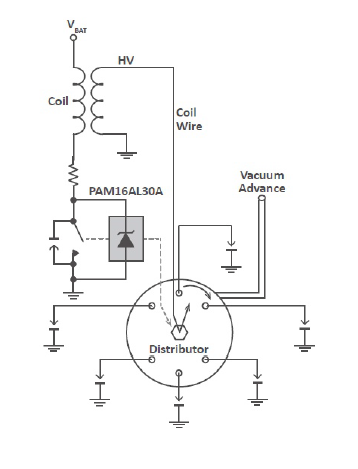

Protection against load dump

During sudden accidental disconnection ofot the car battery the voltage surge produced by spinning alternators can raise high, the usual method of protecting an automotive electronic subsystem is to shunt the supply voltage with a semiconductor transient suppressor. One example is by using PROTEK’s PAM1 6AL30A device, which is a discrete 1 5,000 Watt, silicon transient voltage suppressor (TVS).

Protecting other systems in the car

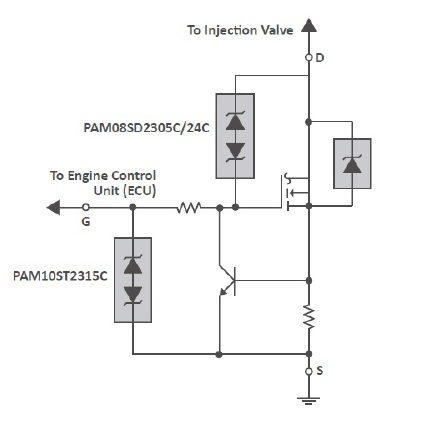

For Infotainment network systems, ProTek's new TVS protection devices include eight TVS arrays. The PAM01SC7905C is designed for the electronic control unit. The PAM02SD231 2 is ideal for USB2.0 as is an alternative TVS array, the PAM1 2SO824. The PAM03SD2303CI provides protection for Bluetooth®. The PAM04ST430502 and alternative PAM1 8DF2L0521 cover automotive LCD displays. The PAM05SC700504F and alternative PAM1 9DF2L0521P are ideal for car audio. The PAM06SC7905S and alternative PAM21SC790501H TVS arrays guard automotive antennas. The PAM08SD23xxC series and alternative PAM24DF1 605 are designed for automotive control buttons. For body network systems, the PAM02SD231 2 TVS array is ideal for lighting sensor control units. The PAM08SD23xxC series and alternative PAM07DF23K24 provide protection for reverse sensor control units. The PAM09SD2305HP is designed of air bag sensors. The PAM1 5ST4305 steering diode / TVS array is designed wiper sensors. For chassis network systems, the PAM08SD23xxC series of TVS arrays covers fuel injection interfaces.

The PAM09SD2305HP is ideal for the ignition. The PAM1 6AL30A is designed for voltage protection of electronic braking systems. The PAM1 0ST23xxC series of TVS arrays shields electronic steering control systems. For power network systems, ProTek Devices provides the PAM08SD23xxC series and the PAM1 0ST23xxC series of TVS arrays. These are for protection of power distribution (1 2, 24 and 36V). And, the PAM1 6AL30A and PAM07DF23K24 TVS components provide voltage protection for the car battery.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2016/1 | Elektronet : elektronikai informatikai szakfolyóirat, 2016. (25. évf.) 1. sz. 24-27. old. |

| 2 | Elektronet online | PROTEK túlfeszültségvédő szupresszor- diódák az autóelektronikában |

| 3 | Hungarian version | PROTEK túlfeszültségvédő szupresszor diódák alkalmazása az autóelektronikában |

| 4 | Jövő Gyára 2016/3 | 2016. 3. sz. 21-22.o. |