Ian Doyle - ProTek Devices, Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Load dump protection with PROTEK TVS diodes in automotive electronics

18 May 2016

Summary :

AAs in the previous paper about automotive overvoltage protection we described, automotive electronics is continuously developing features in order to enhance driving experience, which also challenges circuit protection manufacturers to follow the trends by introducing proper circuit protection solutions. Talking about standard bus systems, infotainment systems, LED based lighting systems and Advanced Driving Assistance systems, like park assist and collision avoidance are all getting more or less common in new cars. Mandatory safety enhancements such as TPMS are also made to increase reliance on electronic technologies within the automotive sector and therefore require dedicated attention from circuit protection point of view. We reviewed earlier the TVS based overvoltage solutions for the most common standard interfaces, in this paper we make a study about solution for one of the most massive overvoltage event, the so called load dump.

Electrical transients in automotive electronics

Common Transients in Automotive Systems that impact the performance of the electronics can be generated from different sources which are shown in the table. Designers of the infotainment, lighting, drive train, body or chassis/safety subsystems of car electronics need to consider the circuit protection standards. Providing proper circuit protection helps ensure safety while reducing warranty and service related costs for manufacturers. For automotive systems’ immunity to electrical fast transients, the Automotive Electronics Council (AEC) provides a discrete semiconductor qualification standard. The AEC-Q1 01 standard refers to automotive circuit protection standards.

Different transient are involved like:

- Electrostatic discharge [ESD] test based on human body or machine model.

- Transient created by unclamped inductive switching.

- Load dump pulse, which is generated when a load to which a generator is delivering current is abruptly disconnected.

Voltage transients can be categorized into three types: ESD, Surge and Load dump. Electrostatic discharge (ESD) occurs, when a charge is exchanged between two objects of different charge potential, mainly between human beings and metal objects. Usually a visible spark is generated as a result of breaking down the isolating dielectric between the objects. This is featured by 2-1 5 kV (level 1 -4) air discharge voltage, relative small energy and short (ns) duration.

The surge is a different kind of transient overvoltage event, that is characterized by longer (microsecond) duration, large energy. A surge voltage is mainly caused by a transient of an inductive switching. Load dump is a long duration, usually millisecond long overvoltage event, in car electronics this applies to disconnecting a battery while it is being charged by the alternator. Signal levels can be as high as 1 74 V and may take up to 400 ms to decay. Automotive electronic systems design engineers should be aware of ISO 16750 Road Vehicles — Environmental conditions and testing for electrical and electronic equipment. Further revision to ISO 16750-2 was released in 2012. ISO 16750-2 applies to electric and electronic systems/components for road vehicles describes the potential environmental stresses and specifies tests and requirements recommended for the specific mounting location on/in the road vehicle.

| Paragraph | Description |

|---|---|

| 4.2 | Direct current supply voltage |

| 4.3 | Overvoltage |

| 4.4 | Superimposed alternating voltage |

| 4.5 | Slow decrease and increase of supply voltage |

| 4.6 | Discontinuities in supply voltage |

| 4.7 | Reversed voltage |

| 4.8 | Ground reference and supply offset |

| 4.9 | Open circuit tests |

| 4.10 | Short circuit protection |

| 4.11 | Withstand voltage |

| 4.12 | Insulation resistance |

Table: ISO 1 67502 Road Vehicles – Relevant Paragraphs for Transient Protection

| Time Duration | Cause | Voltage Amplitude | Energy Level | Frequency Of Occurance |

|---|---|---|---|---|

| 400 ms | Load Dump | < 202 V | > 10 J | Infrequent |

| Steady State | Failed Voltage Regulator | 18 VB | Infrequent | |

| < 320 us | Inductive Load Switching | 80 V to 300 V | < 1 J | Often |

| 200 ms | Alternator Field Decay | -100 V to – 40 V | < 1 J | Each Turn Off |

| 90 ms | Ignition Pulse, Battery Disconnected | < 75 V | < 0.5 J | < 500 MHz Infrequent |

| 1 ms | Harness Coupling | < 200 V | < 1 J | Often |

| < 60 ns | Electrostatic Discharge | < 25 kV | < 10 mJ | Infrequent |

Need for load dump protection

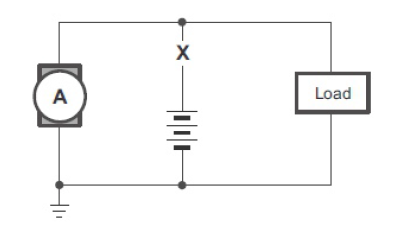

Paragraph 4.6 of the table “Discontinuities in supply voltage” contains a sub section 4.6.4 Load Dump. A load dump occurs when the load to which a generator is delivering current is abruptly disconnected. In automotive electronics, this applies to disconnecting a battery while it is being charged by the alternator.

Paragraph 4.6.4 describes the simulation of the voltage surge produced by spinning alternators when the battery or some other significant load is accidentally disconnected.

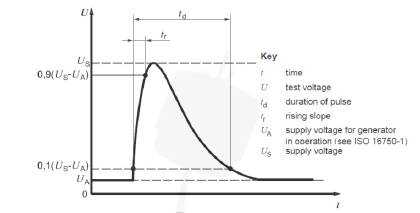

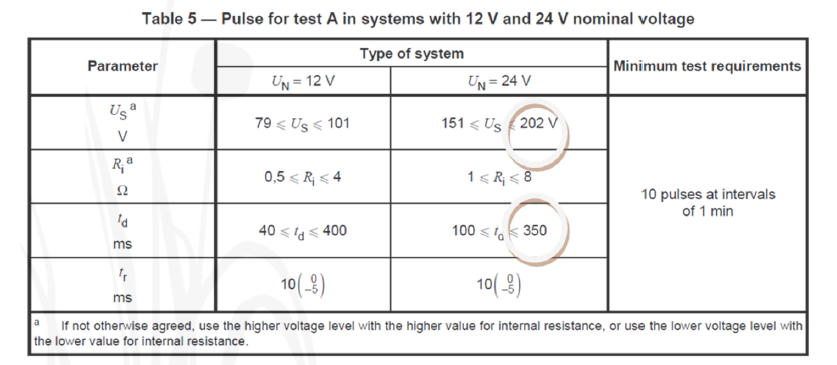

Reviewing the below Table, the applied transient can be as high as 202 V and may take up to 400 ms to decay. Considering that series resistance could be 1~2 ohms, the surge current can be over 50 A for the 350 ms duration which design engineers need to consider for the system. The repetitive test of 1 0 pulses with 1 min intervals requires any Load Dump protection solution to sustain the current handling, with resettability and without drift on resistance on the line.

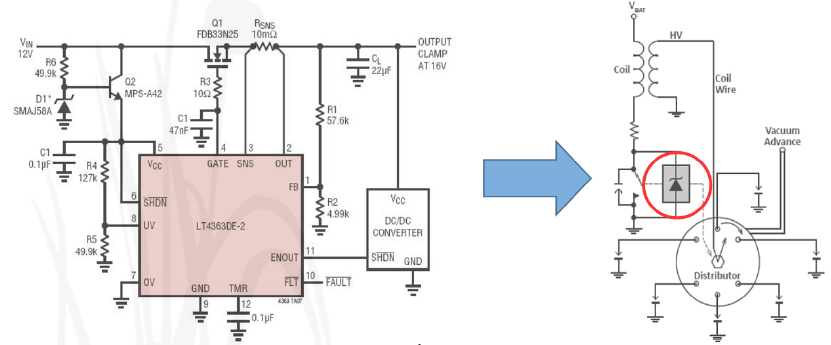

Switching solution for Load Dump Protection

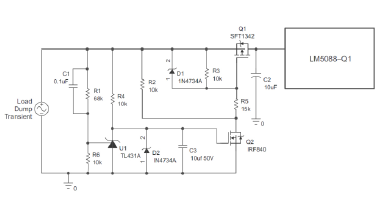

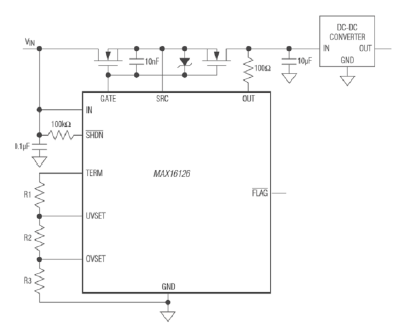

One of the possible power supply designs uses LM5088 (wide input range non synchronous buck controller) with protection for load dump protection in automotive environment. The solution provide protection to load dump transients by disconnecting the input supply to the controller or electronic subsystem for the specified duration of the pulse and then reconnect with a fixed delay when conditions return to normal. The circuit below is the series disconnect circuit used to prevent LM5088 against load dump transients.

The circuit is designed using TL431A precision programmable reference used for precision series disconnect.

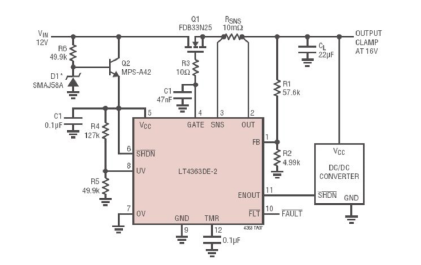

LM5088 has the input operating range up to 75 V that is acceptable for typical load dump transients, thus, allowing the controller operation but for transients above the controller upper operating range, input supply needs to be disconnected. Other recommended Load Dump Protection Application Circuits from Linear Technology and Maxim Integrated are shown below.

The number of the discrete components, as well as the manufacturing and PCB costs are quite high.

Shunting solution for Load Dump Protection

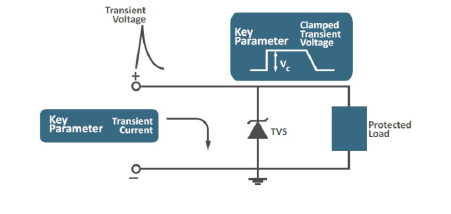

The basic method of protecting an automotive electronic subsystem is to shunt the supply voltage with a semiconductor transient suppressor device. The challenge for semiconductor industry is to generate a single TVS device that must be capable to supporting the higher 30A to 65A surge currents (1 0 pulses every minute for 1 0 minutes) over the longer 350ms to 400 ms pulse duration as specified by the ISO 1 6750-2 standard.

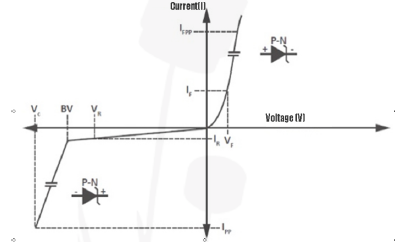

Semiconductor silicon TVS diodes contain a P/N junction similar to a Zener diode but, with a larger cross section which is proportional to its surge power rating. These diodes are clamping devices that limit voltage spikes by the low impedance avalanche breakdown of the P/N junction.

The electrical characteristic V-I curve shown above is similar to that of a Zener diode. However, TVS diodes are 29 designed and characterized for transient voltage suppression, while Zener diodes are designed and specified for voltage regulation. With a TVS diode, an electrical transient is clamped instantaneously and diverts the applied surge current away from the protected device.

Automotive electronic designers typically select nominal resistance Ri values (2 ohm for 1 2 V and 4 ohm for 24 V systems) and reduced td duration (40ms for 1 2 V and 1 00ms for 24 V systems) to minimize the surge current during load dump transients. They use lower surge rated SMCJ (1 .5kW) or SMDJ (3kW) TVS diode devices in Load Dump protection circuits but the question is, if this protection robust enough for current usage conditions with increasing electronic systems in automotive vehicles. The ProTek Devices PAM8S series provides an industry best combination of surpassing ISO 1 6750-2 Load Dump testing while also delivering an industryleading lowest clamping voltage at 48.4 volts. Compliant to AEC-Q1 01 reliability standard, the series consists of 1 5 highpower TVS arrays covering a range of reverse stand-off voltage needs, from 1 4.0 to 43.0 volts. The TVS diode series is provided in JEDEC DO-21 8AB package which is RoHS and REACH compliant. With a TJ = 1 75°C capability, the device is suitable for High Reliability and Automotive Requirements. This single TVS diode solution for Load Dump Protection provides distinct advantages on manufacturing costs and PCB real estate savings over the discrete MosFET & DC-DC Controller solutions for leading IC manufacturers. This single TVS diode solution for Load Dump Protection provides distinct ad-vantages over competing technologies.

- Simplified Solution Circuit – 1 6 components reduced to 1 discrete component.

- Reduced Installation Costs – BOM and Manufacturing Installation costs

- Reduced PCB real estate – Single DO21 8AB Package

- Reduced Lead Times sourcing single device.

- Excellent MTBF calculation for single DO21 8AB with 2 leads over multiple components.

- Fast setup for Functional Test of System

The Protek PAM08 solution, with a single component, protects an automotive electronic subsystem by shunting the excess supply voltage with a semiconductor transient suppressor device.With a TVS diode, an electrical transient is clamped instantaneously and diverts the applied surge current away from the protected device.

With a TVS diode, an electrical transient is clamped instantaneously and diverts the applied surge current away from the protected device. The single TVS device in JEDEC DO-21 8AB package is capable to shunting the higher 30A to 65A surge currents (10 pulses every minute for 10 minutes) over the longer 350ms to 400 ms pulse duration as specified by the ISO 16750-2 standard.

The new PAM8S for Load Dump Protection provides distinct advantages over competing technologies and enable designers to add new features to automotive electronic systems.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2016/4 | Elektronet : elektronikai informatikai szakfolyóirat, 2016. (25. évf.) 4. sz. 18-21. old. |

| 2 | Elektronet online | Load Dump jellegű túlfeszültség elleni védekezés az autóelektronikában |

| 3 | Hungarian version | Load dump jellegű túlfeszültség elleni cédekezés az autóelektronikában |

| 4 | TechStory M2M | Load Dump túlfeszültség elleni védekezés az autóelektronikában |