Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Li-ion batteries and their circuit protection solutions

18 April 2014

Summary :

Lithium-ion is one of the most popular rechargeable battery technology providing energy for today’s consumer applications. Its perfect energy density, not remarkable memory-effect, slow loss of charge in standby mode and the light weight makes Li-ion battery to be used for energy storage for many electric vehicles, especially to provide alternative solution for heavy lead acid batteries. In order to preserve the long cycle life, the very sensitive lithium cells should be protected against overcurrent and overtemperature conditions, that may be caused by short circuit of terminals, abusive charging or changing circuit failures. In this article we would like to make an overview about the lithium-ion technology via introducing a leading manufacturer EVE Battery’s line up as well as the possible circuit protection solutions from TE Circuit protection.

Lithium-ion structures from EVE Battery

EVE Energy Co., Ltd was founded in 2001 and specializes in high-energy lithium batteries. EVE is the largest provider of Primary lithium cells within China. In 2010, EVE has substantially increased their investment in the manufacturing of the rechargeable (often called secondary) Lithium-ion batteries. New state of the art automated production lines have been installed. This will allow EVE to make significant contributions to the field of lithium-ion energy storage including polymer lithium-ion cell, prismatic Li-ion, Cylindrical Li-ion cell and power batteries.

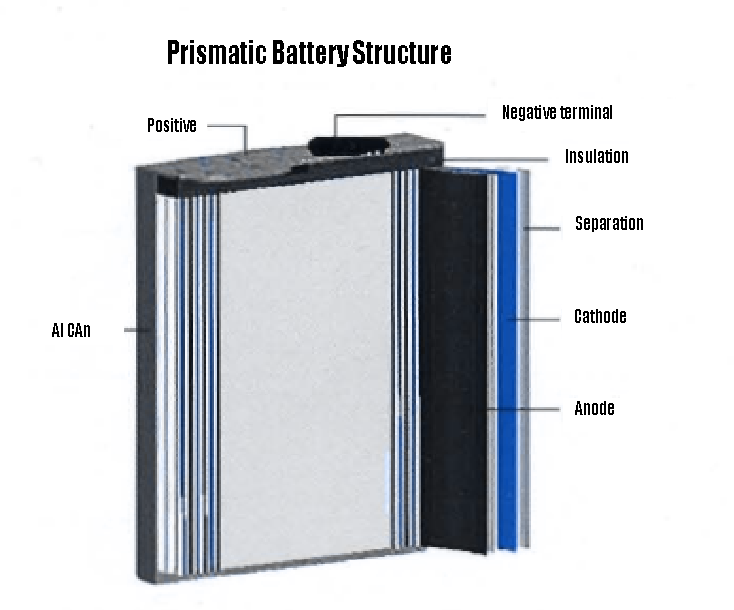

Prismatic and cylindrical versions are used in the area of mobile devices (phone, laptop), backup power sources (UPS), power tools and E-bike. Prismatic cells using space optimally due to their layered construction. There are no universal formats, when the housing of the design allows a few millimeters extra in the housing of the end product, the manufacturer designs a new pack for the sake of higher capacity. High volumes justifies customization.

Prismatic cells deliver capacities of 20 to 30Ah and are often used for electric powertrains in hybrid and electric vehicles. The prismatic cell improves space utilization and allows flexible design but it is less efficient in thermal management and have a shorter cycle life than the well known cylindrical design.

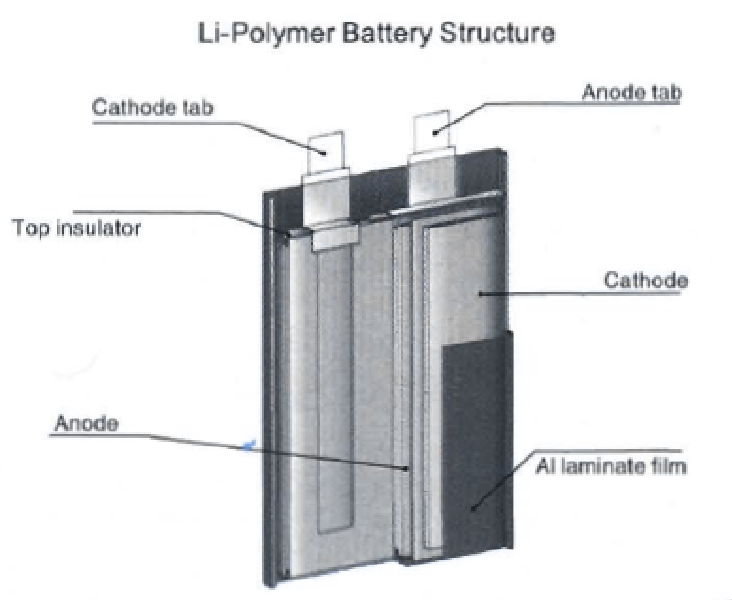

Polymer Li-ion versions could be used much more flexible due to their changeable outlook, manufacturers can shape them as they wish for devices such as MP3/4 players, Bluetooth applications, GPS as well as for E-book readers. LiPo batteries are mainly composed of several identical secondary cells in parallel to increase the discharge current capability, and often available in series packs to increase the total available voltage.

All Li-Ion cells expand at high levels of state of charge (SOC). If the cell is uncontained, delamination can occur, which reduces the reliability and cycle life. The had case of cylindrical cells provides that containment, while pure polymer cells are not contained. Therefore, to achieve the rated performance, a battery composed of polymer cells must include a strong external casing to retain its shape. Overcharging a Li-poly battery can cause an explosion or fire. During discharge while on load, the load has to be removed as soon as the voltage drops below approximately 3.0 V per cell otherwise the battery will no longer accept a full charge and may have problems holding voltage under load. Li-poly batteries should be protected by circuitry that prevents over-charge and deep-discharge. Compared to the lithium-ion battery, Li-poly has disadvantages of life cycle degradation.

Although manufacturers protect Li-Ion batteries very well, several incidents related to lithium-ion batteries are known, so there are concerns about their overall safety. Some of these cases have been linked to overheating, which may result fire or explosion. A number of standards have been developed to provide manufacturers with guidance for safe construction, based on consensus between manufacturers’, consumer advocacy organizations’ and insurance companies’ interests.

The international standards of the following associations are currently in use to assess some of the safety aspects of primary and secondary lithium batteries:

- Underwriters Laboratories (UL)

- Institute of Electrical and Electronics Engineers (IEEE)

- National Electrical Manufacturers Association

- International Electrotechnical Commission (IEC)

- United Nations (UN)

- Japanese Standards Association

- Battery Safety Organisation

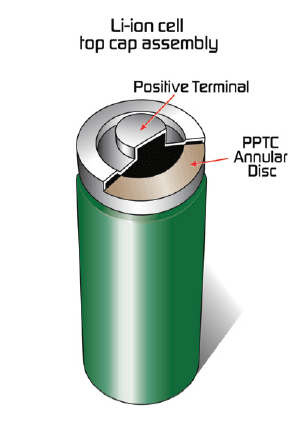

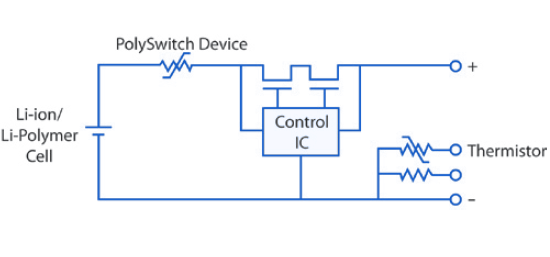

Circuit protection for Lithium cells

The special electric characteristics and the thin flat form have made TE Circuit protection Polyswitch PPTC annular disc devices perfect solutions for lithium cell applications. At normal circumstances the PolySwitch, which is a series element in the circuit has a small resistance, and hardly has an influence on the performance, due to the conductive particles in the polymer form a conductive low-resistance network. As a response of the overtemperature event the device trips, increases the resistance quickly and reduces the current of the device to the level that can be safely carried by the battery cell. The heating can be the increase of the ambient or the cell temperature, or can be generated by resistive I2R heating of an overcurrent condition. The PolySwitch PPTC annular disc latch to high resistance state, when fault occurs, and automatically reset when the fault is removed, enabling the battery to restore normal operating conditions.

Rechargeable battery packs, which may be used in digital cameras and other handheld devices are sensitive to overcurrent and overtemperature conditions caused by sudden external shorting or runaway charging. These failures can raise the temperature of the battery causing cell damage or even smoke. An unprotected battery pack can typically deliver up to 100A of current, when shorted with a low resistance material, so the power dissipation of the cell’s internal impedance causes huge overheat. This can lead to the damage of the cell or in critical situation smoke. In case of resistive shorting object, the excess heat outside of the battery can also reach few hundreds degC, which can cause fire on the surrounding flammable materials. The other usual problem is the overcharge of the battery. One way is to experience a runaway event, when – usually due to the charger fault – it des not stop supplying current to the battery , when it is fully charged. Abusive charging may occur, when an incorrect charger is used, and an overvoltage or overcurrent condition causes battery cell overcharge. During a typical overcharge fault, the cell temperature rises as the overvoltage across the fully charged cell forces chemical degradation of the internal structure. Using a PolySwitch device, the rising temperature helps the device trip already on lower current. Usually the Li-ion pack include an active primary overvoltage, undervoltage and overcurrent detection safety circuit, and PolySwitch can be used as a secondary level protection.

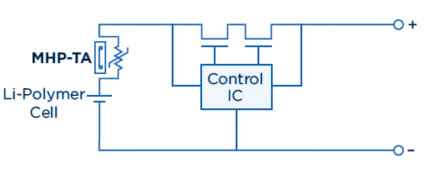

For Li-ION and Li-Polymer based packs a PolySwitch VTP,VLR,VLP or MXP strap device is recommended, due to their special construction. Unlike the SMD devices, the strap is welded to the cell body, which helps heat transfer from the overheated cell to the PolySwitch device for faster thermal acting.

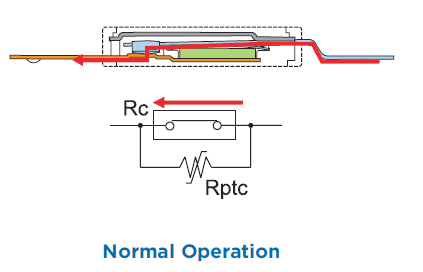

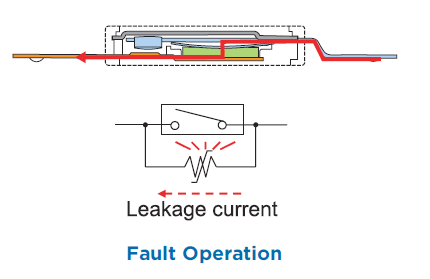

PolySwitch devices are often used to replace bimetal or thermal fuse protectors. Bimetals are often bulky and expensive, and also have bad latching characteristics. However they have rapid response, good current handling capabilities and low resistance at the point of contact. Especially with the growing popularity of Polymer Li-Ion batteries, the cells are often subject to higher discharge rates, high pulse currents and higher charge currents. These high rates cause the cells to operate on higher temperature, which is a risk of damage. Currently very few protection solutions are available the offer low thermal cut-off temperatures as well as high hold current ratings in a small package. The advanced version of TE Circuit Protection’s MHP ( Metal Hybrid PPTC) device, the so called MHP-TA ( Thermal Activation) series combine a PPTC and a bimetallic circuit breaker in parallel.

The PPTC acts as a heater to keep bimetal latched , when fault occurs, so the device is able to interrupt current, when detects a high cell temperature. Like this it can protect the cell from fatal overheating.

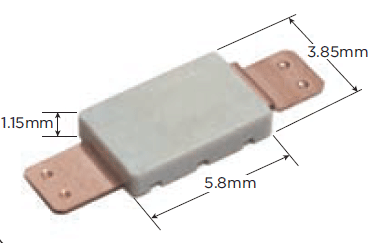

The MHP-TA product line consists of two device series based on different levels of current carrying capacity. The low-current devices offer approximately 6A hold current at 25°C and high-current devices of approximately 15A. By offering two levels of carrying capacity in an ultra-low-profile package (L: 5.8mm x W: 3.85mm x H: 1.15mm), the MHP-TA device addresses the issue meeting high hold-current rating requirements while also providing a cost- effective, space-saving method of overtemperature battery protection in the latest generation of consumer electronics.

Endrich offers ready to use primary Li-Ion cells in many shapes from cylindrical AA and AAA , via CRxxxx button to super pulse caps, as well as secondary rechargeable batteries and battery packs. Moreover these Endrich can be at customers service with circuit protection ideas for battery protection.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2014/3 | Elektronet : elektronikai informatikai szakfolyóirat, 2014. (23. évf.) 3. sz. 22-24. old. |

| 2 | Elektronet online | Li-ion akkumulátorok és az alkalmazott áramkörvédelmi megoldások |