Wolfgang Endrich

Directly on mains voltage - alternative to PSUs

2 October 2015

Summary :

Suitable circuits allow LEDs to be operated directly on mains voltage without a power supply unit. The solution is scalable and space saving. Its also allows LEDs to be dimmed evenly and without flickering. The electric light bulb served us well for over 100 years since it was invented by Edison in 1879. Light emitting diodes were discovered as luminescent crystals about 60 years ago and have made triumphant progress since then. Power supply units for operating LEDs have also been available for many years. But since the invention of ICs which can be operated directly with 230 V AC while supplying LEDs with direct current, the question arises whether conventional power supply units are still required. LED lights operated with alternating current have been successfully sold as series produced items for many years. In the beginning these were Retrofit GU10 lamps with 8 to 10 W, followed by built in spotlights and floodlights with 120W and more.

Use of AC drivers

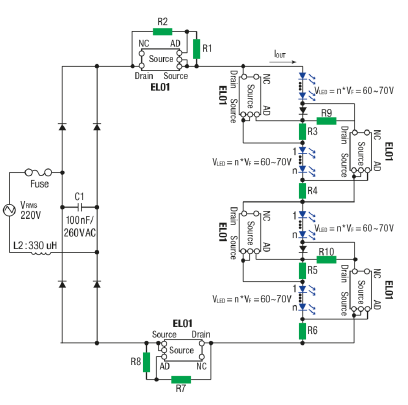

The use of AC chips not only means uncomplicated designs. It also allows good dimming characteristics, AC or DC operation, low space requirements for the power supply and a long service life. Today the Asian markets offer a comprehensive range of AC-operated products. EuroLighting developed the compact EL01 chip for controlling LED lights directly with 230 V AC, at low cost and with simple circuits. It increases the service life of the power supply to the level of light-emitting diodes with 50,000 hours and more. Components such as electrolytic capacitors and transformers are not required. The sample circuit in figure below shows how an LED lamp with power supply can be built with only few components.

Simple operating principle

The operating principle of the AC chips is simple: The mains voltage is rectified and fed into an AC direct driver without smoothing.

This driver pulses with 1 00 to 1 20 Hz and supplies the LEDs with a constant current and a voltage between 60 and 70 V. This allows LEDs from a variety of manufacturers with different voltages to be controlled directly as long as 70 V is not exceeded within a group. Any power level can be achieved through parallel connection of several groups.

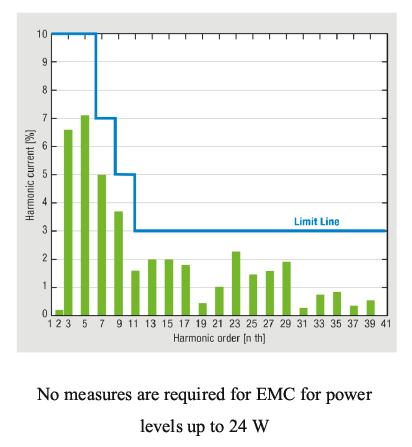

In an existing circuit, the power level can easily be adjusted by changing the resistance values. One advantage of circuits with the EL01 is dimmability with leading edge control and TRIAC. Additionally, up to 24 W no further measures are required for complying with electromagnetic compatibility. Higher power levels can be achieved with small changes. An integrated NTC is used for power reduction from 85 °C, the PFC achieves a power factor of over 0.98 and an efficiency of 85 to 90 %. Total harmonic distortion (THD) is below 1 8 % and the working temperature ranges from -40 to +85 °C.

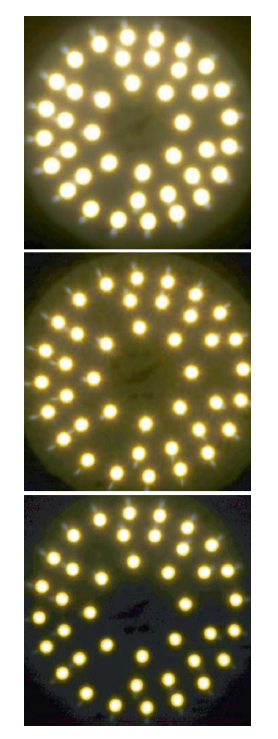

Even dimming with the EL01 : an LED module with 5 W (top), 2 W (middle) and 1 W (bottom) Some solutions in the market swich off individual LEDs during dimming - left: 6W; right: 4W)

Flicker-free light is ensured at all power levels which meets the Japanese regulations for flicker-free light.

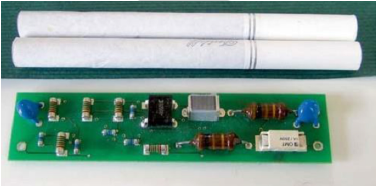

In addition, the circuit can alternatively be operated with AC or DC. Space requirements are low: a circuit with 30 to 40 W only requires the space of two cigarettes.

Even dimming

LED drivers that can be operated with mains power are offered by several renowned manufacturers. These often differ substantially from the EL01 , though.

Circuits with the EL01 require several chips of this type which spreads dissipation to several surfaces Competitors' products generally consist of a large chip, focusing the dissipating heat on one point. There are also significant differences during dimming. The EL01 chip allows even dimming by simultaneously dimming all LEDs in one circuit.

Some competitors' chips implement sequential dimming of the individual groups. Individual LED groups are switched off in sequence. This means the beam of light is not homogeneous and the LEDs of the lowest groups are used more often than those in the top group, which can affect the service life of the light-emitting diodes.

Variable for customer requirements

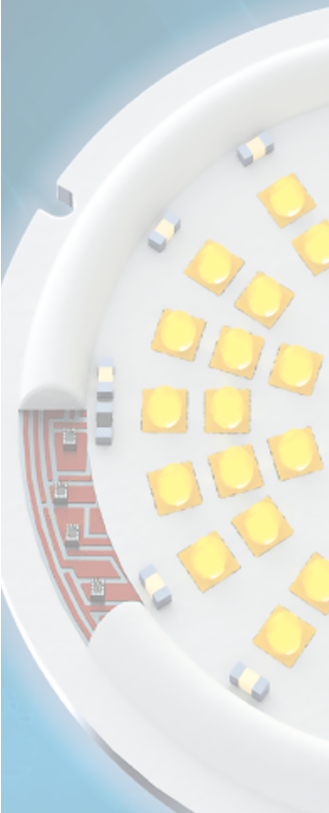

EuroLighting offers two solution approaches for the AC chips: The power supply can be integrated into a compact printed circuit board in the lamp housing. Alternatively, the circuit can be located at the edge of the circuit board on which the LEDs are mounted. The IC dies are bonded directly onto the circuit board and protected with epoxy resin (title image).

Based on this technology, round LED circuit boards with integrated power supply are offered as standards products with up to 40 W for a module diameter of 54 mm. Round modules with an open design and 1 50 mm diameter are available with up to 1 20 W. Also available are illuminated surfaces with an area of 280 x 280 mm² and 1 2 W, which can be connected as desired, as well as strip elements for use in LED tubes. Another advantage of these AC circuits is that LEDs from different manufacturers can be exchanged in the circuits.

This allows adaptations for reasons of price or light colour and light output. The result is a modular design with many common parts which can be varied depending on customer requirements.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2015/6 | Elektronet : elektronikai informatikai szakfolyóirat, 2015. (24. évf.) 6. sz. 16-18. old. |

| 2 | Elektronet online | Hálózati feszültségről működő LED-modulok |

| 3 | Hungarian version | Hálózati feszültségről működő LED modulok - Eurolighting |

| 4 | Revista Española de Electrónica online | LED + driver en una placa – all in one |