Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Photometric principles used in LED classification - binning

8 February 2013

Summary :

The photometry is the measurement of the electromagnetic radiation by means of the response of the human eye, which makes it changing with wavelength and different person to person. In order to provide a consistent basis for principles of photometry, international standards define observer functions that can be used. In this abstract we are going to give an overview of definitions used in the LED lighting to describe the light output of the devices, we make a summary on optical definitions (like color temperature, color rendering, brightness) and electrical properties ( e.g. forward voltage), that LED manufacturers base their classification on by means of binning.

Photometric measurements and optical properties

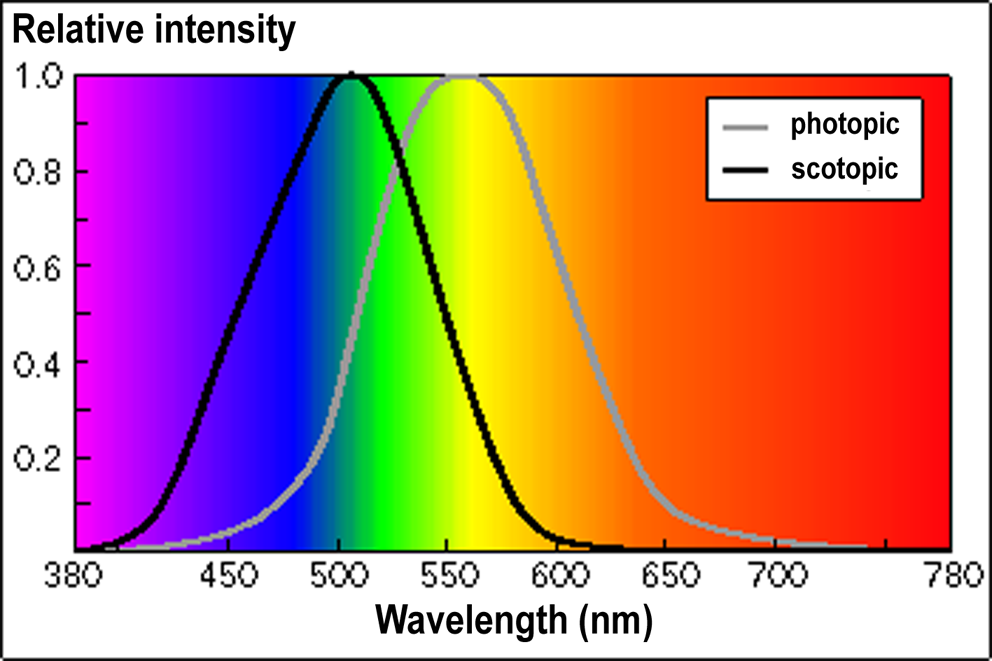

The standards created for providing internationally-agreed observer functions usually describe two methods, the V(λ) , which is used for day-time light levels (photopic vision) , and the V’(λ) function ,which is used for low lighting level (scotopic vision). For intermediate light levels (twilight) the CIE system of mesopic photometry provides smooth transition between V(λ) and V’(λ). Detection systems used for measurements have to have similar response than the human eye in the above circumstances, therefore different V(λ) and V’(λ) photometric sensors have to be used.

There are several measures that are used in the literature and datasheets of LED manufacturers to describe the light output of the different devices, and for the engineers that is not always obvious, which measure describes what, and makes hard for them to compare existing well proven light sources with LED based solutions just by measures. In order to set up a clear view, we are going to review all the definitions.

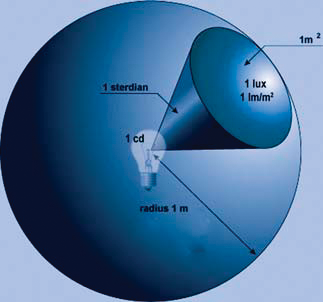

Luminous intensity measures the luminous output from a source in a specific direction into unit solid angle. The SI base unit of it is the candela (cd), but its definition is only valid on a single frequency and with a defined radiant intensity, because the human eye responds differently for the same radiated energy on different colors (the most sensitive is at 555 nm). By definition the candela is the luminous intensity of a source in a given direction, that emits monochromatic 555 nm radiation with the radiant intensity of 1/683 Watt per steradian. The steradian is the cone of light spreading out from the source illuminating one square meter inner side of a 1m radius sphere. (see the figure 1).

If the source and its radiation angle is small, the brightness will appear to be intense even if its emission is small. Therefore the apparent brightness of this source when looking directly into it should be differentiated from its luminous emission, that should be described by candela per square meter.

In the practice light sources never give monochromatic radiation of 555 nm (yellow-green), but radiate over the whole visible spectrum. The human eye needs more energy in the red and the blue-violet ends of the spectrum to give the same clear view. In practice the luminous intensity of the white light sources is defined by multiplication of emitted power on a certain spectral wavelength and the sensitivity of the human eye in this frequency, relative to the yellow-green wavelength. This efficiency factor has been represented by the V(λ) curve, obtained by averaging results from experiments with many people. Using this curve that is possible to make a relation between experienced human sensation of light with measurable physical concept of energy. The sensors used for light intensity measurement meet with the standards describing curves for photopic and scotopic vision.

PThe candela is a unit of intensity, but light source can be emitting 1 cd spherical to all directions, or could also be only a narrow beam radiation of 1 cd. The intensity will be the same, but the total energy flux is something different.

The total luminous flux, an other often used measure in the literature is for describing the amount of light emitted from a source in all directions ( full sphere, 4 П steradians) and its measurements also reflect the varying sensitivity of the human eye to different wavelengths. Its measuring unit is the lumen (lm), which is in relation to the candela as

1 lm = 1 cd * 1 sr.

As the full sphere has the angle of 4 П steradians, the source uniformly radiated all over the sphere has the total luminous flux of

1 cd * 4 П steradian ≈ 12.57 lm.

Manufacturers of lamps often provide the light distribution diagrams of their products. These diagrams show the luminous intensity as the function of the direction (angle from the axis of main beam). On the figure it is visible that the lamp emits around 400 cd in a direction of 45° from its axis, but directly forwards 490 cd. No matter how far is an object in these directions standing, the emission in a certain direction will be the same, candela value is independent of the distance, but we still cannot tell how much light the object is receiving. The diagram gives us only the emitted intensity in certain directions, however engineers always need to calculate the light energy falling on the object standing in a certain distance in a certain direction from the source.

This energy makes the object visible, and its density gives the illumination.

Illuminance is the next common measure of the technical literature. This is measured in lux, and takes into account the area over which the luminous flux is distributed. For a point source and a surface normal to the direction of view, illuminance equals luminous intensity divided by distance squared.

Looking at our lamp’s light distribution curve, the candela value for 60 degrees is 230, this is equal with 230 lumens radiating in a cone of one steradian, which covers one square meter on the surface of a 1 m radius globe. In this distance 1 m2 of surface of an object would receive 230 lumens (230 lux) , but 3 meters away, only the one ninth of it cca 25.6 lux.

A flux of 1000 lumens concentrated to a 1 m2 area lights up it with an illuminance of 1000 lux. Same flux distributed on 10 m2 area will result only 100 lux. Therefore the definition is :

1 lx = 1 lm/ m2

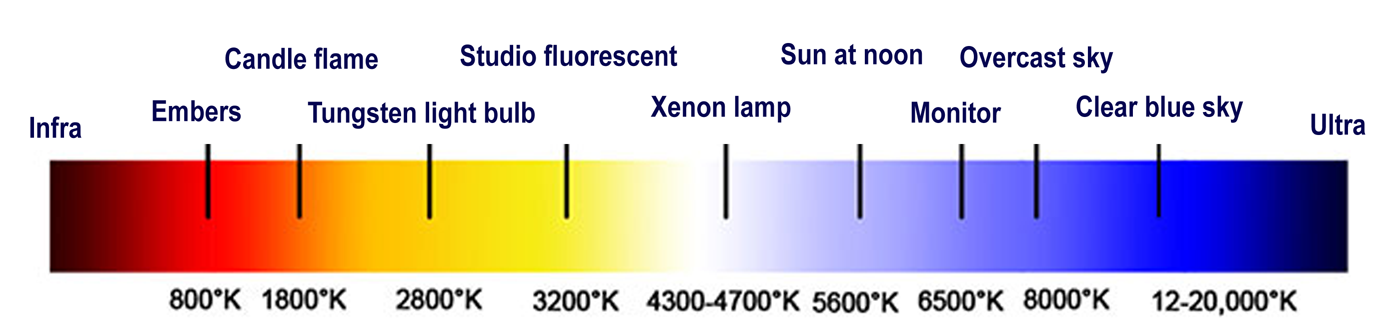

After discussing the measures describing the “strength” of the light, we need to talk about the color feeling of a light source. As we would like to know more about the general lighting, the “white” light should be targeted. One of the main property of LEDs and light sources the so called color temperature. It could be most simply described as the color characteristics of light, usually either warm (yellowish) or cold ( bluish), measured in Kelvin degrees. The more technical definition assigns a numerical value from a scale to the color emitted by a light source. This Kelvin scale is defined as the temperature of a heated black body object, which starts to glow radiating deep red (as low burning fire) and shifts slowly towards white hot. These kind of light sources are called incandescent radiators, and they have continuous spectrum, therefore can render all the colors of a lit object. The Sun closely approximates a black body radiator with the color temperature of 5900K.

LEDs and other light sources, that are not incandescent radiators are described with Correlated Color Temperature (CCT) , which is based on closely matching done by the human eye when comparing light of these sources with incandescent radiators.

Lights with correlated color temperature do not have an equal radiation at all the wavelength in their spectrum, therefore they would have difficulties to accurately render certain colors. Light sources are characterized by their ability to render all colors with the he so called CRI (color rendering index). The maximum CRI of 100 has been assigned to incandescent radiators. Professional use requires CRI of 90 as a minimum.

Classification of LEDs used for general lighting applications - binning

The fast development of white LED technology has lead to a significant potential for a lot of application like general lighting, automotive lighting and backlighting. Meeting with the necessary regulatory lighting standards still give a lot of challenges to LED manufacturers. In order to maximize effective utilization in production of LEDs, the practice of binning has been introduced. The two most important dimensions are color and flux, which parameters are collected as the part of LED manufacturing process, and are the basis for the component binning. This process is the most important for lamp manufacturers in order to control performance, cost and lead-time. To understand the binning, the LED production steps has to be understood briefly.

Some of the LED manufacturers has wafer-fabs in their facilities, some others buy the chips on the market. The heart of a white LED is a semi-conductive blue chip that is created on a round single wafer, that will be sliced to extremely small dies. These dies later are placed into a lead frame and wire bonds are inserted. As a know-how of the different manufacturers or packaging houses a special phosphor is added either as a coating or suspension within enclosure. The assembly is encapsulated to the required LED package. The chips would of course define a number of properties of the LEDs, like brightness and forward voltage, but the contents of the used phosphor create also significant variations that impact optical behavior. Although most of R/D activities and huge investment of money targets reducing this production variation, the process is still not capable of producing highly consistent end product on reasonable cost level. In addition to continue improve to maximize the yields, LED producers still need to sort their production into lumen, color and forward voltage bins. This helps to lamp manufacturers to target their production to an economic sortiment at the end of the day.

LED manufacturers always have a target value when starting new production lot by means of brightness, CCT and forward voltage, and they select their chip and phosphor accordingly. Most of the finished products in the yield will fall into the target area and the distribution of the properties could be described with a Gauss curve.

If a customer accepts to buy a very wide range of LEDs ( in any of the binning criteria) price and leadtime are surely improved, but the variety of the end product by means of color, brightness and power consumption could result high probability of negative impacts to end-customers. On the other hand requiring a very narrow accepted tolerance, the manufacturing costs could increase rapidly, as much more LEDs have to be manufactured in order to find enough proper ones in the yield. Therefore the LED manufacturers provide different binnings for different prices, providing acceptable tolerances for optical and electrical parameters within a bin.

The most critical bin criteria on product performance are color temperature and brightness. Binning for light output is a very straightforward linear function, LEDs are individually measured and sorted by lumen output into prescribed standard ranges defined by the manufacturer. So end customers can select bins or set of bins that best matches for their purposes. The more exact brightness is targeted, the less bins are purchased by the customer, the higher the price becomes.

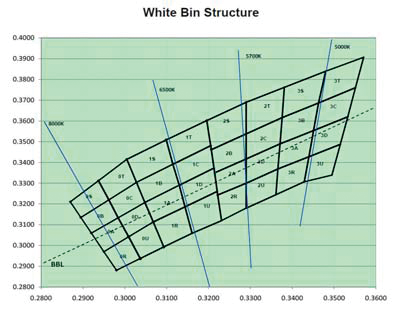

Binning for color temperature is however a more complex process. Color temperature bins are defined by (x,y) coordinates on the CIE 1931 Chromaticity Diagram. Color science is based on the physiological particulars of the human retina for the reception of light and color. Colors are defined by the ration f red, green and blue colors, which correspond to bandpass tuned cones of the retina. The white is located in a small area in the middle of the paraboloid, and binning will correspond to small regions within the white center of the color space.

As shown in the figure of Dominant Opto Technologies white bin structure, the full area of white color is divided into subgroups based on the (x,y) coordinates’ ranges, these bins are grouped as quadrants around the standard chromaticity lines for a specified color temperature. The larger the bin size, the more variation around the standard color temperature is accepted, and the price and lead-time is most probably lowered.

As the LEDs are usually driven with constant current sources, the power of the single device depends on the voltage drop across the LED. This so called forward voltage binning is introduced to keep control over the I2R tolerance of the LEDs used by the lamp manufacturer. The closer the forward voltage of the Leds are, the less variety of different individual power consumption values appear when huge number of LEDs are used in the same time, and total power consumption of the complete light engine could be kept in a desired range. When customer buys LEDs without forward voltage selection,- especially in constant voltage supply configurations - there might be problem with unique brightness of parallel connected LEDs of the same type.

Manufacturers of LEDs may also introduce other selections and provide different kind of binnings to provide reasonable pricing and clear picture to their customer. With color LEDs we often find binning on the wavelength, which is important for designers of systems demanding precise color output.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2013/1 | Elektronet : elektronikai informatikai szakfolyóirat, 2013. (22. évf.) 1. sz. 16-18. old. |

| 2 | Elektronet online | A LED-szelekciók fizikai alapja |

| 3 | Hungarian version | A LED-szelekciók fizikai alapja – Fénytechnikai alapfogalmak és a binning |

| 4 | Jövő Gyára 2019/1 | 2019. 1.sz. 9-13.o. |