Kiss Zoltán - Export Manager - Endrich Bauelemente Vertriebs GmbH

Endrich IoT infrastructure - Endrich cloud database service and related hardware development

18 August 2020

Summary :

A major challenge we face today is digitalization of industrial processes, extending machinery with low power, feature rich microcontrollerbased electronics to collect sensor readings and forward data with LPWA communication channels to a Cloud Database in order to build up the “BIG DATA” – the knowledge base of the future.

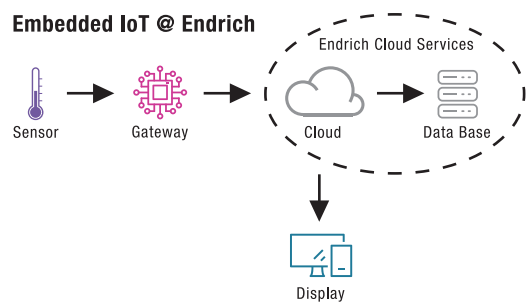

Embedded IoT @ Endrich

A mass of sensor readings needs to be organized into central databases for future processing so as to meet the expectations of Industry 4.0. The Internet of Things, or IoT provides the ecosystem to deal with this challenge. We review these potentials based on the IoT infrastructure system developed mainly for demonstration purpose by Endrich GmbH, a leading electronic spare part distributor in Europe, by showing an example how to work with a modem using Narrow-Band IoT technology and introducing the cloud based database service which was created by the company engineers to help IoT developers at the customers. Endrich GmbH has developed an online sensor network infrastructure for the Embedded World 2020 exhibition, where every component of this hardware have been supplied by the manufacturers represented by the company. The beginning of the processing chain – like in a real-world application – consists of sensors detecting and measuring different physical quantities, which are processed all the way to cloud database storage and visual data representation at the end. There is a sophisticated gateway in between, which collects the sensor readings, preprocesses these data and sends it through a communication channel to a cloud based database service, where it can be displayed after processing, or used for any purpose appropriate for a given task.

Sensor and Gateway

The industrial expectations towards the complete infrastructure are high and diverse

- Minimalization of device, installation and maintenance cost

- Many years of battery lifetime

- Selection of suitable components for a complete solution

The Endrich IoT concept is to implement this structure and provide our partners with hardware and software solutions on several levels.

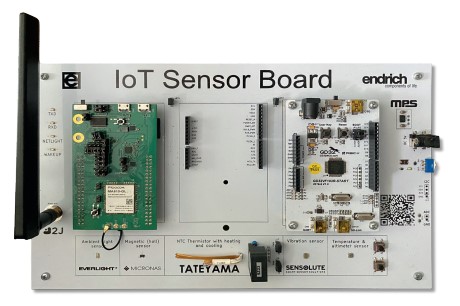

The First Step:

Endrich has started to develop – as the first step – a microcontroller driven sensor board equipped with narrow band GSM communication module. This Sensor & Communication Board as a hardware, together with the cloud based background network infrastructure (Endrich Cloud Database Service Software) offer a fully working concept of a general IoT solution, and it has been exhibited on national and international expos and conferences earlier in this year. Data provided by the Everlight ambient light sensor (ALS), the Tateyama and Semitec temperature sensors (NTC), the magnetic sensor from TDK-Micronas (Hall) and Sensolute miniature vibration sensor get collected by the newly developed GD32V103 RISC-V microcontroller from Gigadevice, and sent through the communication channel to the server. The telecommunication connection is implemented by a Fibocom MA510 module, which supports both NB-IoT and GPRS networks, and posts data using UDP protocol for storing in the Endrich Cloud Database Server – created for our partners. The panel size is for demonstration, a real application would be much smaller in size.

The Second Step:

Endrich has also prepared an equivalent compact solution for other MCU platforms, so we can provide an IoT end point as a communication shield for third party MCU boards. This device fits to the commercial Arduino Leonardo boards and also to GigaDevice evaluation kits for ARM® Cortex® M23 or RISC-V microcontrollers converting them to an IoT end point with sensing and communication capabilities. Endrich is providing The Endrich IoT concept is to implement this structure and provide our partners with hardware and software solutions on several levels. ENDRICH IOT INFRASTRUCTURE – ENDRICH CLOUD DATABASE SERVICE AND RELATED HARDWARE DEVELOPMENT this conceptual development infrastructure as a platform, not as a product, we still live on component sales, but supplement it with development support sharing reference circuit design, software code and providing access to our cloud database during the product development.

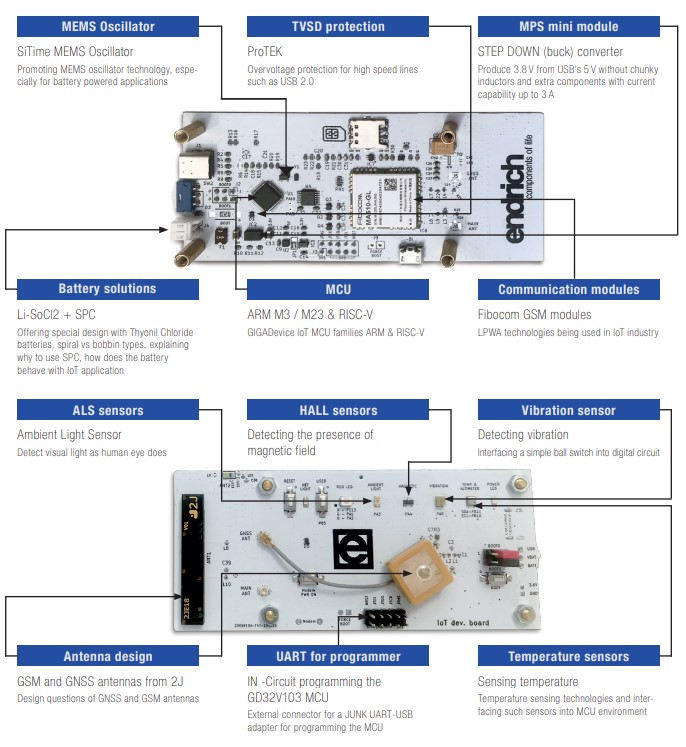

The Third Step:

The third development step integrates all IoT functions (sensors, MCU and communication) into one single PCB. The constructed IoT endpoint is capable of vibration and magnetic field sensing, ambient light intensity, temperature and air pressure measurement, altitude change calculation, and reporting the data through GSM network. This IoT board works autonomously as an island device powered by Lithium battery or USB power bank, and also reports GPS location thus can be applied even for vehicle superstructure tracking (such as cold storage or truck cargo compartment.)

The IoT board acts as a development evaluation board for the IoT technology. Can be used as MCU evaluation, GSM modem evaluation. For this purpose, external connectors are available for the MCU and the Modem UART interfaces

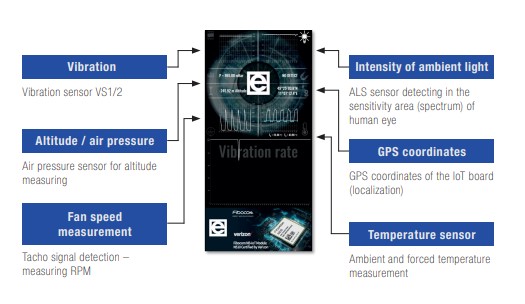

Data Visualization

Data visualization is possible on any connected device, mobile phone, panel PC or industrial TFT monitor. The only requirement is a web browser, since the Endrich Cloud Database contains a WEB server providing visual display service. This interface can be customized in a certain level for customers’ own sensor applications.

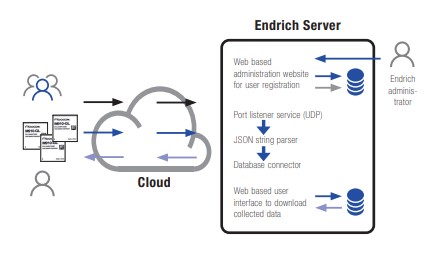

Endrich Cloud Database Service

Apart from our usual service to help finding and testing the appropriate components for a given IoT solutions, Endrich recognizing the need for background services, which also support development engineers providing cloud database service to administrate and store structured sensor data for later processing. The service can be used during evaluation and development until the developer is ready with his/her own cloud-based backend. The data is transferred in UDP channel using a predefined format and supports any number of end points.

How can we help our customers?

We are happy to share the reference designs of the sensor interfacing, help microcontroller programming and selecting the best fitting components for any IoT applications our customers are developing. Our demonstration purpose devices are using advanced IoT technology, and help to review the operation of the sensors, to handle microcontroller data input and to implement wireless communication. We take care of the appropriate voltage leveling, power supply and conversions. The card can be energized by advanced lithium primary battery, we are available for consultation on ER or CR batteries, rechargeable Li-ion accumulators or DC/DC converters or power supplies. We advise on MCU frequency control using MEMS oscillators, help in EMI issues and also overvoltage protection. We are happy to organize online or personal demonstration, please address any question to the author at z.kiss@endrich.com.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2020/5 | Az Endrich IoT ökoszisztéma – hardver fejlesztések |

| 2 | Elektronet online | Az Endrich IoT ökoszisztéma – hardver fejlesztések |

| 3 | Jövő Gyára 2020/4 | Az Endrich IoT ökoszisztéma – hardver fejlesztések |

| 4 | South-East Europeand Industrial Market 2020/3 | Endrich IoT infrastructure - Endrich cloud database service and related hardware development |

| 5 | South-East Europeand Industrial Market online | ENDRICH IOT INFRASTRUCTURE – ENDRICH CLOUD DATABASE SERVICE AND RELATED HARDWARE DEVELOPMENT |

| 6 | Magyar Elektronika online | Az Endrich IoT ökoszisztéma – hardver fejlesztések |

| 7 | Magyar Elektronika 2020/7-8 | Az Endrich IoT ökoszisztéma – hardver fejlesztések |

| 8 | Pressebox online | Die Endrich IoT Infrastruktur |

| 9 | Hungarian version | Az Endrich IoT ökoszisztéma – hardver fejlesztések |