Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Miniature vibration sensors and applications

7 October 2013

Summary :

General electronics designs often require a simple device, which is able to detect movement in order to trigger wake-up event for the circuit. A usual way is using ball switches, that are simply but effective devices, such as the versions Endrich offers from Sensolute in both uni- and omnidirectional versions. Unlike previously used mercury switches, the micro vibration sensor is environment friendly by using non-toxic substances and therefore it is RoHS and REACH compliant.

General features

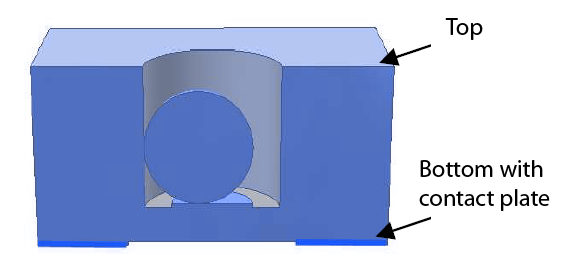

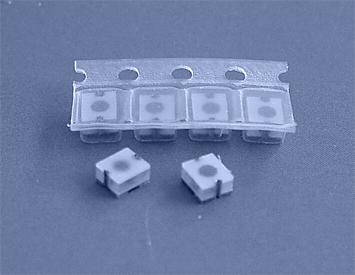

The VS1/2 Micro Vibration Sensor detects motion and vibrations through a gold-plated, moving micro-ball encapculater in a micro barrell, that forms together a ball-switch.. Due to its small size of 2,85 x 2,45 x 1,7 mm, the sensor is suitable to use in very small electronic devices by applying SMD technology, and can easily be integrated into any designs. The hermetically closed capture makes it resistant against harmful environmental impacts such as humidity or presence of acids, while also having no dangerous substances inside. It could be used in the temperature range of -20°C -+70 °C / -40°C - +85°C and it is fully-automatic lead-free SMT mountable.

A micro-ball with a diameter of as small as 0.8mm is located in a cylinder formed by the inner wall of the sensor housing and can move freely inside this cavity. Even the smallest movement or vibration causes the ball to move so that closes or opens two gold-plated contacts, one as the sidewall of the hollow and the other on the bottom of the sensor. The pulses resulting from this vibration should be evaluated by application-specific electronics and are implemented in corresponding switching signals. As soon as the sensor detects no more movement, the electronics could switch to the power-down mode after an application-specific time delay. This seems very easy, and theoretically could be easily implemented and used to switch off electrical dvices such as handheld devices being not in use, vehicle electronics, that should not be used when standby, or shut down conrol circuits of machines, that are switched off, all for saving battery lifetime and power consumption.

Application specific electronics

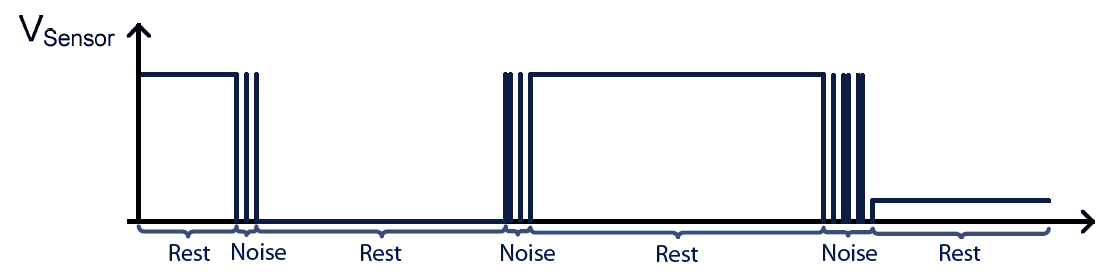

As the sensor does not provide a definite „on” state when vibration occures and „off” state at rest, we need to implement an electronics that can evaluate the environmental circumstanes. The output of this ball-switch device will be a series of transitions between the logical high and low DC levels. Moreover this both versions of the sensors are not neccessarily closed when no vibration detected.

The unidirectional version is equipped with contacts on one side resulting different sensitivity depending on sensor orientation. This sensor is suitable for motion and position detection. The omnidirectional version is independent of the sensor orientation. This sensor is suitable for motion-detection only.

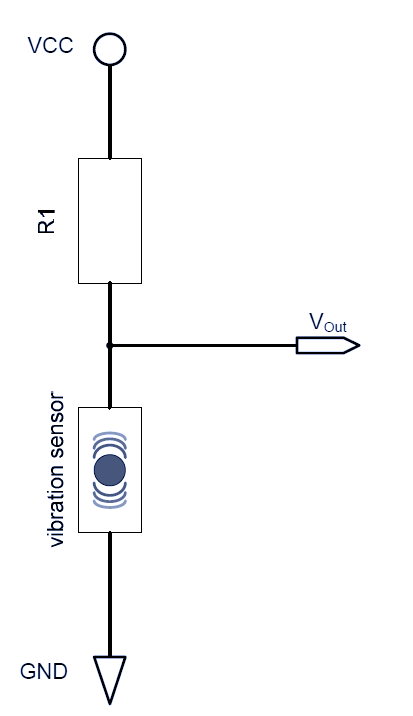

Being at one DC-level a slight vibration may cause the sensor signal to toggle, that cannot be easily filtered out therefore has to be handled by the μcontroller software. With the unidirectional VS1 sensor it is possible to get a defined open state by building it upside down, as the micro sphere is on the top of the cavity, where is no contact pad present. On the figure the simpliest circuit is shown, where the resistor is neccessary to limit the current to a maximum value of 2 mA.

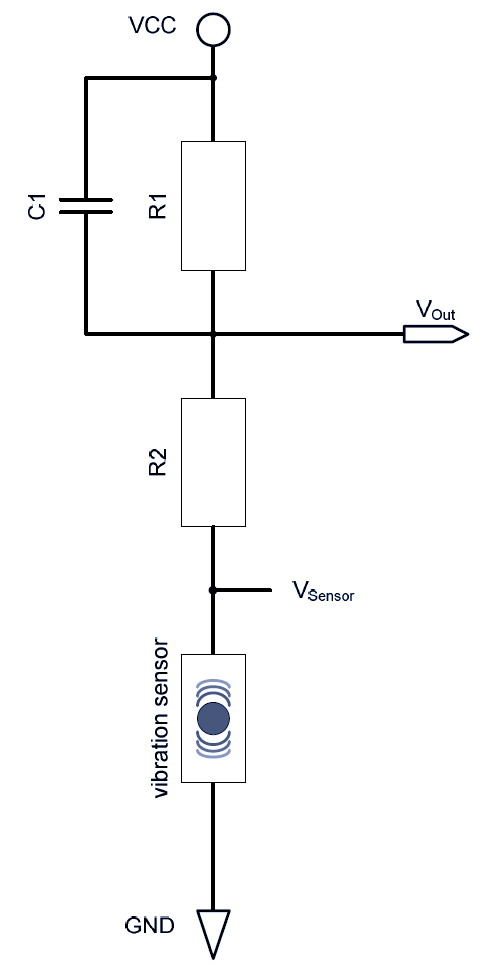

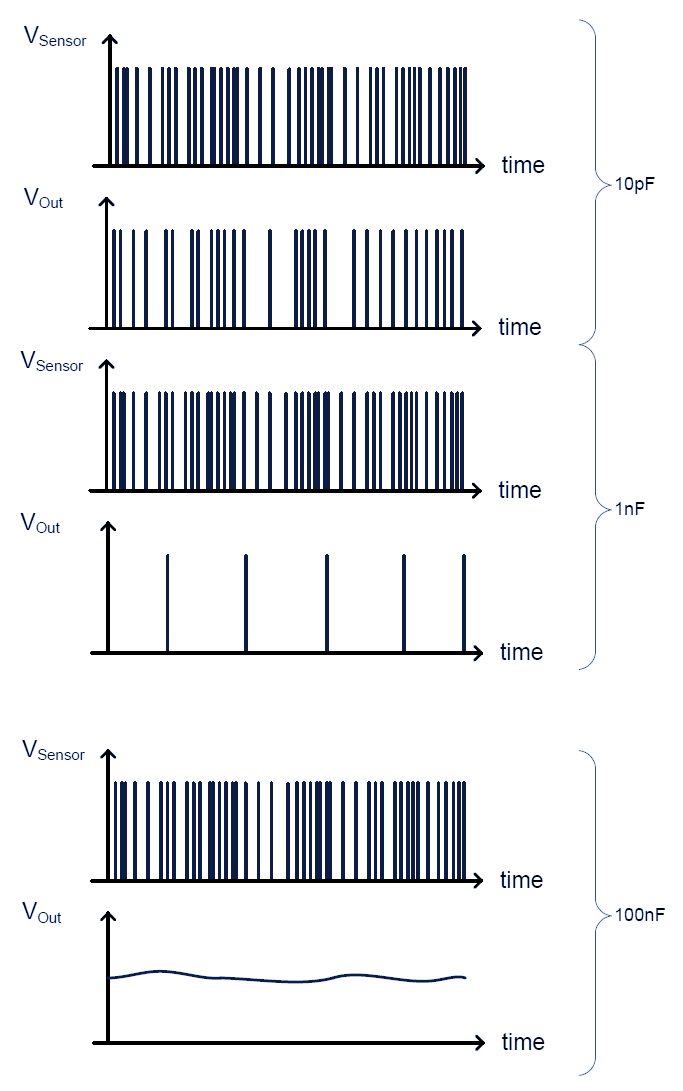

If the sensitivity of the device should be reduced , a small capacitor could be used inparallel with the resistor. In this case is better to make a voltage divider, by means of using two serial resistors, because if the capacitor is directly on the imput of the sensor, the large inrush current could damage the contacts. Therefore a solution shown in the figure 4 is better. In case using higher capacitance, the peaks of the output voltage will be integrated into an average analog value. For the resistie divider R1=5M and R2=100k .. 1M could be chosen.

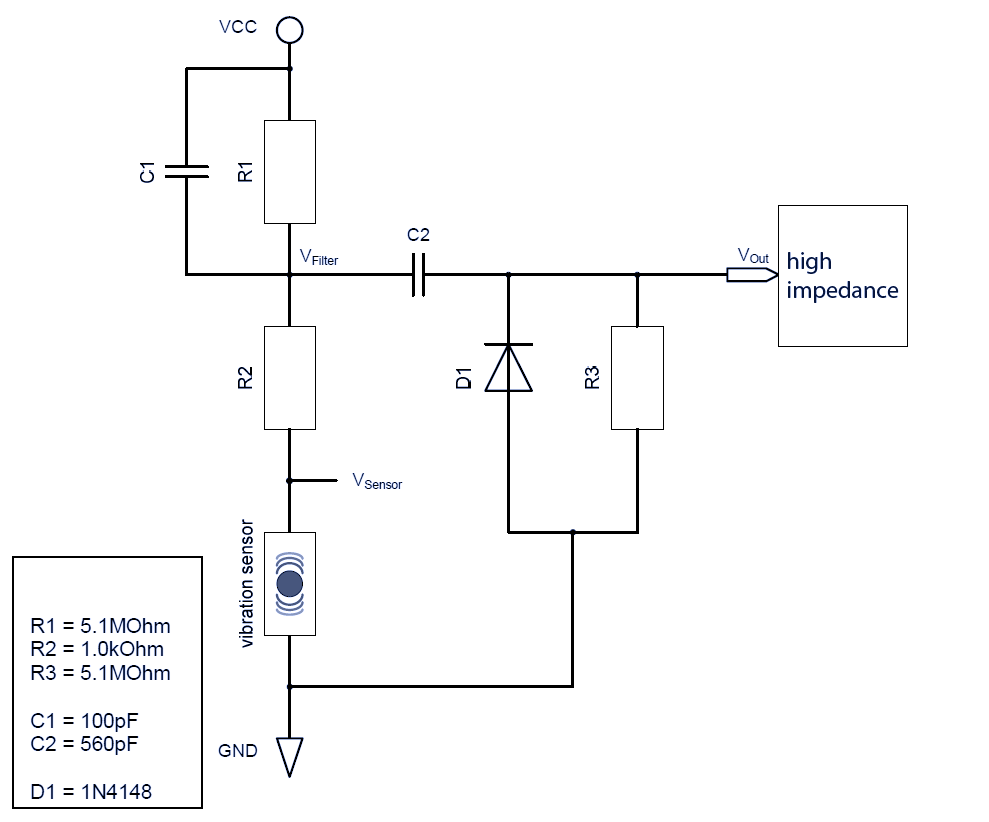

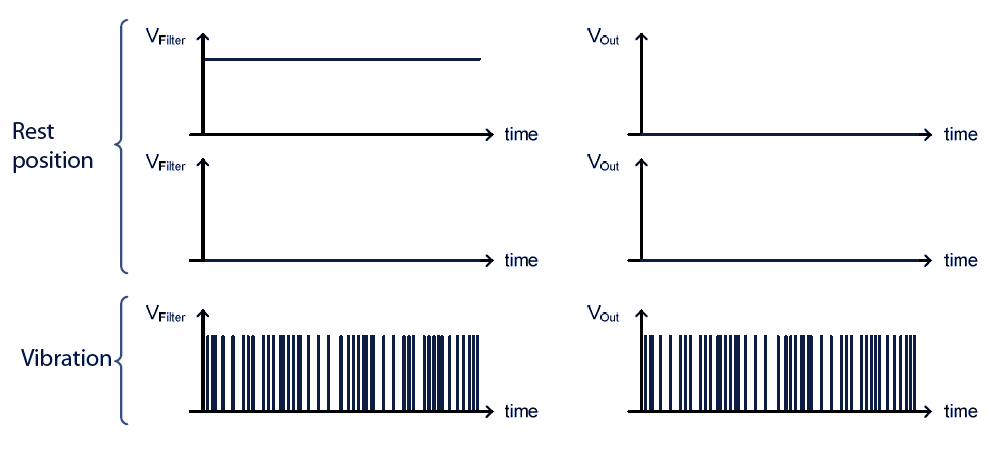

In case a definite „low” state is required, when the sensor does not detect vibration, a similar circuit to the one shown of figure 6 could be used. The capacitive voltage divider determines the filter characteristics, C2 should be at least 5 times larger capacitance than C1. The c1 value of 100pF will result high sensitivity, while the 100nF value would turn the the peaks of the output into an integrated average voltage. (Figure 7)

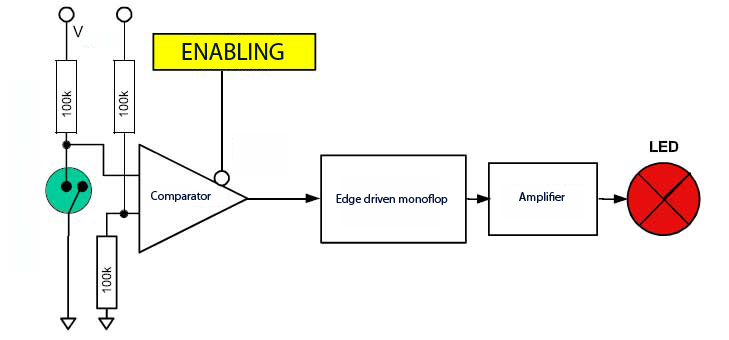

Detecting the output voltage the best to use a monostable multivibrator as an edge driven monoflop, which could be seen on the figure 8.

Application areas

Micro Vibration Sensors are suitable for a wide range of applications. Bicycle lights, which turn on when it is dark and the bicycle is moving; LCD remote controls which switch off when inactive or batter operated handheld devices all need to have an energy saving sensor solurtion, that could be provided with the vibration sensors.

- active RFID systems

- GPS tracking systems

- bicycle computers

- access control systems

- hands free sets, car kits

- electronic dog collars

- security systems

- patient monitoring

- asset monitoring

- data loggers

- remote controls with LCD displays

- shavers with LCD displays

- bicycle lights

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2013/6 | Elektronet : elektronikai informatikai szakfolyóirat, 2013. (22. évf.) 6. sz. 26-27. old. |

| 2 | Elektronet online | Miniatűr rezgésszenzorok |

| 3 | Hungarian version | Miniatűr rezgésszenzorok |

| 4 | TechStory M2M | Miniatűr rezgésszenzorok |