Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Capacitive touch control

5 June 2019

![]()

Summary :

The widespread use of smartphones and tablets has made the touch control common and self-evident and forcing developers to replace mechanical user interfaces (switches pushbuttons) with electronic versions in an increasing number of areas of electronics, thus avoiding failures due to wear out or fatigue and also utilizing on the innovative gesture control provided by the technology. Remote controls, home appliances, intercoms, consumer electronics are increasingly featured with such human-machine interface solutions, which can be implemented simply with capacitive touch control technology. A further advantage of this technology is that it provides the device with greater resistance to environmental influences (water, dust, etc.), since it is not usually necessary to open the housing. In this article, we review the physical foundations and capabilities of capacitive touch and proximity sensing.

It is a common trend today that microcontroller manufacturers equip their devices with basic touch control functions that allow simple touch buttons, basic gesture control, to be integrated into the final product without the need for separate circuits. These solutions are generally perfectly suited for replacing mechanical switches, rotary knobs and sliders with advanced capacitive touch controls, however, the need for precise positioning or using extreme surfaces (wood, thick glass control) require even more advanced solutions. Examples of such use-cases include the touchpad of computers or remote controls, the controls of modern ovens, kitchen appliances, or the touch switches integrated in furniture. The fabless South-African manufacturer Azoteq Ltd, whose patented technology is in fact licensed to major microcontroller producers, responses with its innovative solution featuring the highest sensitivity on market for such challenges.

Basics of capacitive sensing

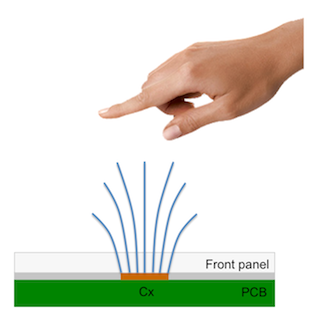

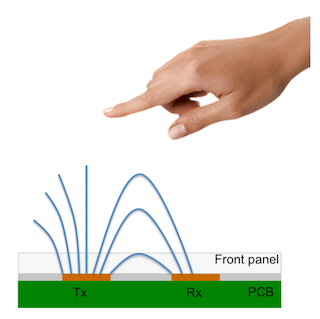

Capacitive sensors are conductive surfaces which capacitance changes when the human body, hand or finger is approaching or touching it. This capacity may be the mutual capacitance between two measuring electrodes or the self-capacitance between an electrode and earth.

The magnitude of the change in capacitance is very small, ranging from 10 pF for touch, 1 pF for close proximity, and only 0.05-0.1 pF for proximity and either a microcontroller A/D converter with a suitable software library or a dedicated touch controller can be used for the detection. The following principles are used for sensing:

- RC acquisition principle based on the change in charge and discharge time of the capacitance over a given resistance. When the electrode is touched, this time increases, and measuring the change is suitable for detecting the touch. The integrated touch control functions of microcontrollers often use this principle. It requires software-based time and voltage measurement (GPIO A/D converter).

- Charge transfer acquisition principle based on measuring the charge stored in the capacitance. The charge stored in the capacitance of the electrode is discharged by periodical pulses into a sampling capacitor until its voltage reaches a given value, and the number of periods is counted. The change of the pulse count represents the change of the capacitance. When the electrode is touched, its capacitance grows, and it will be capable of storing more charge and it means less number of pulses until the sampling capacitor reaches the reference voltage. This principle is also widely used in some MCU families with integrated touch control where the analog GPIOs can be used for touch sense.

- Surface ProxSenseTM acquisition principle It is equal to the previous regarding its principle, but the sensing is done with a dedicated hardware providing extreme sensitivity.

- Projected ProxSenseTM acquisition principle In this method based on measuring the charge stored in the capacitance between a driven and receiver electrode is measured also using a sampling capacitor. The dielectric constant between the electrodes is altered as a human finger approximates thus the capacitance decreases. It results in a longer charging time of the sampling capacitor (more cycles) and it makes possible to detect the approaching finger.

The ProxSenseTM trademark is the property of Azoteq (Pty) Ltd, who is a high-tech company in South-Africa represented by Endrich GmbH since 2019.

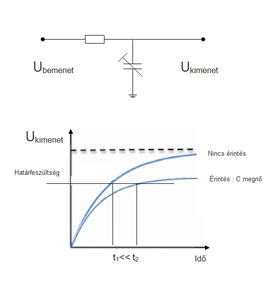

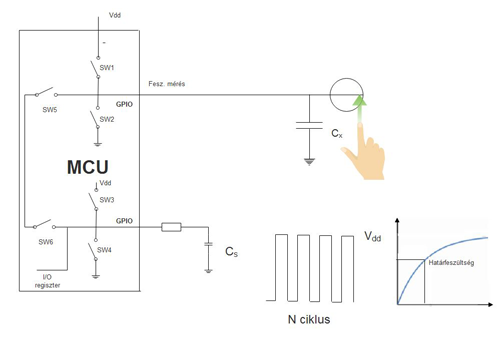

Simple RC touch detection with microcontroller

Simple microcontroller-based touch sense on RC principle

The simplest RC touch key solution can be implemented with a microcontroller and software timing. When the electrode is not touched, its capacitance is constant (Cx), the time required for the R-C member to charge to the set threshold voltage is t1. When the finger is touched, the CT capacitance is parallel to the electrode capacitance, so the resulting capacitance value is increased by about 5 pF (C = Cx + CT), and the charge / discharge time to reach the boundary voltage will reach t2. During the measurement, a timer started when the power rises, measures the charging time until the voltage at the sensor foot reaches a threshold. Easily configurable software libraries are available for performing the measurement. In addition to the cheap and simple construction, the solution is only reliable with stable grounding.

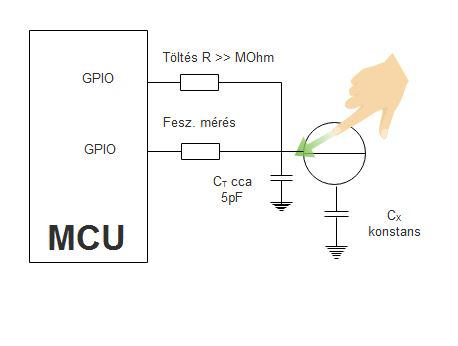

Charge transfer touch detection with microcontroller

The figure above shows the essence of the charge transfer principle. The electrode connected to GPIO of the MCU represent some 10 pF capacitance (Cx - sensor capacitance). The sampling capacitor (CS) having some magnitude smaller capacitance is connected to a different GPIO. Cx is charged to Vdd when the SW1 switch is turned on, and then a part of its charge gets transferred periodically to Cs by switching SW5 and SW6 in a given sequence. The voltage of the Cs is measured the microcontroller through its A/D converter, and number of switching (N) necessary to reach the threshold voltage is calculated. When the sensor touched, its capacitance raises, and more charge will be transferred into CS in a certain period of time resulting that its voltage will reach the threshold in less cycles (n

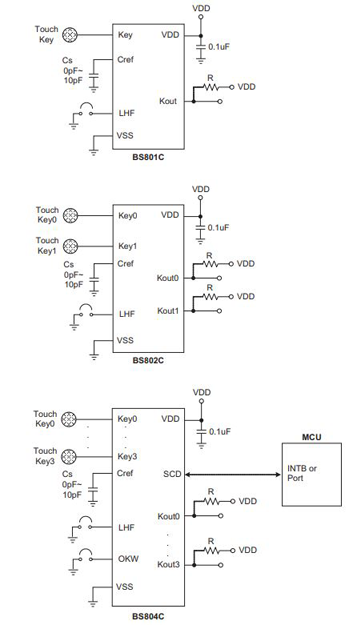

Dedicated touch controllers operated by on the same principle provides a higher level of integration for microcontroller-based application, such as the Holtek BS8xx series. These devices already have a range of features that give the application greater reliability even under harsh environmental conditions, minimize power consumption and work with lower number of components beside the host microcontroller. The more advanced members of the series are also capable for serial communication and return the status of touch keys in decoded form. The MCU can also send commands to the touch controller through the same interface, for example during calibration.

Azoteq ProxSenseTM Touch Controllers

Azoteq is not one of the widely known brand names in Hungary, although the capacitive proximity and touch sensing solutions they have been developing since 2004 can be found in many devices available locally. Using their ProxSense TM technology, they provide the world's most sensitive touch controllers, capable of detecting up to 100 atto Farad (10-16 F) power changes while providing a signal-to-noise ratio of 1000: 1. This represents an increase of 100 times the sensitivity and 30 times the signal-to-noise ratio compared to the prior technologies.

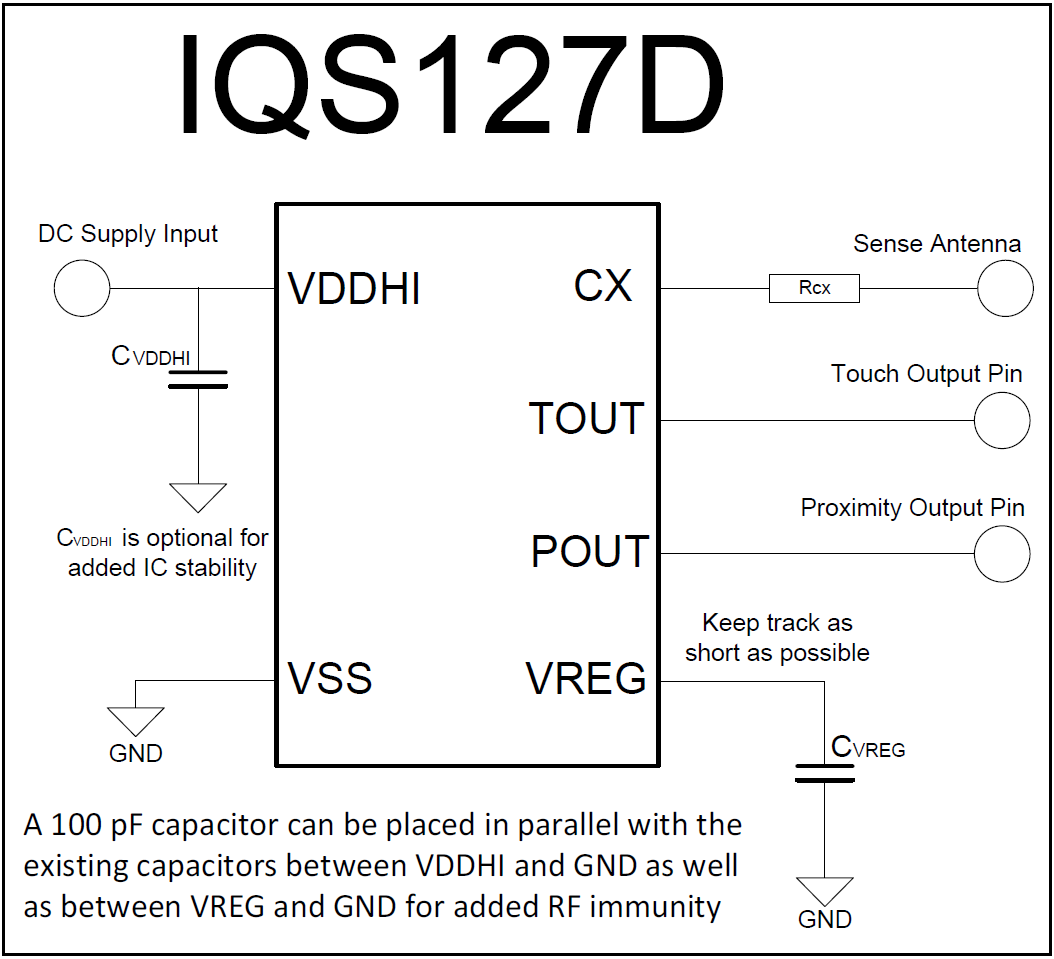

Dual level detection

Such an extreme sensitivity makes possible creating much more sophisticated sensors as simple touch switches. Even the simplest single channel controllers can process two level touch and proximity detection.

While our finger approximates the electrode, the Proximity Output pin will sign first. It can be used for example to switch on automatic backlighting, then the touch signed by the Touch Output pin may activate the required operation. This proximity sensing can be also used in multi-channel controllers as a wake-up signal, since the device can be programmed to be in deep sleep mode until a single live channel detects approximation thus reducing the current consumption of the application.

Swipe Switch

By placing three sensing electrodes side by side, we can create a simple gesture controller that senses a specific direction of a swiping finger. This operation also allows for touch control in hand-held devices, as it distinguishes between simple hold and bidirectional swiping.

Wheel and Slider: level control

Based on multichannel capacity measurement, ProxSenseTM devices can also provide continuous control. When the sensors are located as shown on the figures below, the microcontroller integrated into the controller calculates the position of the wheel or slider from the ratio of the capacitance changes detected on the electrodes, whose absolute value or change can be read numerically.

Wheel and slider electrode layout for self-capacitance measurement

2 channel self-capacitance slider electrode layout

Such electrode layout can be widely used for function selection (like washing machine program) o continues level control. The 3, 7, 9, 12, 16 or more channel controllers from Azoteq are flexibly programmable, channels can be divided into discrete buttons, proximity sensors, sliders, and circular sensor groups, which can operate either on self or mutual capacities measurements.

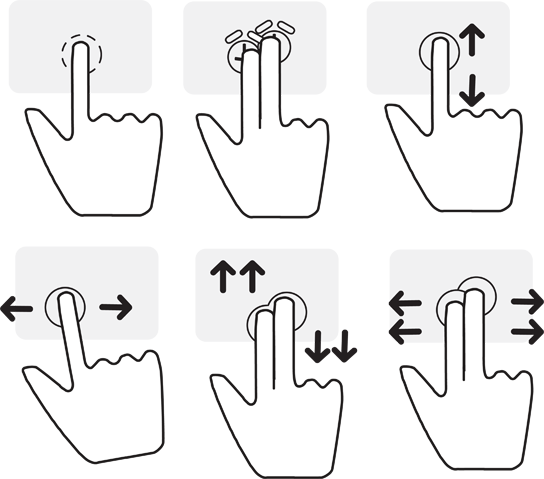

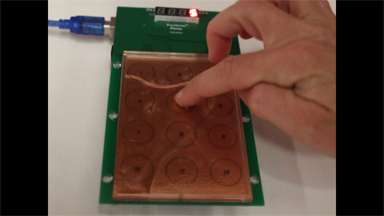

Keypad, Trackpad, Gesture pad7..16 channel controllers have enough channels for keyboard control, touchpad and gesture pad control applications. When the controller operates on a mutual capacitance principle and the electrodes are arranged in a matrix-like pattern, the number of sensing points is the product of rows and columns. Each touch positions can be scanned by stepping the drive (Tx) electrodes and scanning the receiving (Rx) ones.

Trackpad electrode layout

The surface of the touching human finger effects several adjacent electrodes. Due to the high sensitivity of the ProxSense process, the weighted average between the electrodes allows greater accuracy of touch than the electrode density, thus provides stepless motion tracking. The controls feature one- and two-finger gesture recognition, which is great for creating a creative gesture-controlled user interface what can even include dedicated touch keys in certain positions.

Gestures recognized by Azoteq controllers

Touchpad and button on same surface

Azoteq offers not only control ICs, but also professional gesture sensor and touchpad modules in a variety of shapes and features, whether it is rigid or flexible surface, keypad pattern or built-in indicator lights. A selection of finished touchpad modules is also available.

Sense behind thick wood or glass surface

The sensitivity of Azoteq ICs allows be detection through thick insulating material (wood or glass) up to 11 mm This capability is combined with high resolution and high precision. Capacitive switches make unnecessary to break the surface of the decorative casing with holes or cutouts, the electrodes may be hidden inside furniture, household appliances, high-quality casings or thick glass.

Capacitive touch sense on metallic surface wet environment

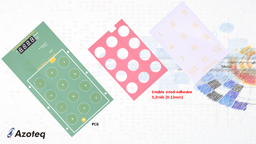

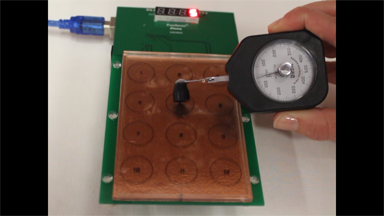

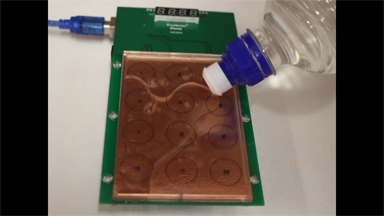

Of course, capacitive sensing through a conductive surface is not possible, but it is possible to create a structure where the change in capacitance resulted by the deformation of the metal surface due to a minimal pressure applied can be used for control like touch control.

If a thin (0.13 mm) solid double-sided adhesive (insulator) is applied in front of the PCB containing the copper electrodes of the sensor, then a thin (<0.1 mm) stainless steel plate or a plastic sheet (<0.3 mm) coated with conductive paste on the inside placed in front, a capacitance is created between the electrodes and the plate.

This capacity changes when a minimal force (<100 grams) applied to such an extent that it can be detected with Azoteq integrated circuits. Such touch panels can be used in vandal-proof and rain-proof environments, even in door phones or shower enclosures.

Support

Designing such sensor electrodes requires a lot of attention and experience from the development engineers. In collaboration with Endrich GmbG, Azoteq extensively supports its partners' design activities in reference design, consultation or review of completed designs. The controls include both programmable and reprogrammable versions. In exchange for a one-time cost and a minimal cost per piece, Azoteq can ship the circuits by programming settings tested by its customers.

Endrich and Azoteq have been working together since 2018. Please contact your local field sales or semiconductor product management at Endrich GmbH for further information.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2019/4 | Elektronet : elektronikai informatikai szakfolyóirat 2019. (28. évf) 4. sz. |

| 2 | Elektronet online | Kapacitív érintésvezérlés |

| 3 | Hungarian version | Kapacitív érintésvezérlés |

| 4 | Jövő Gyára online | Kapacitív érintésvezérlés |

| 5 | Jövő Gyára 2019/5 | 2019. (5.évf.) 2.sz. 30-33.o. |

| 6 | Magyar Elektronika online | Kapacitív érintésvezérlés |

| 7 | Magyar Elekktronika 2019/3 | 2019. 3.sz. 45-49.o. |