Mike Kiraly – Product manager circuit protection, Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Overvoltage protection of indoor and outdoor luminaires

8 May 2015

Summary :

The LED based indoor and outdoor lighting technology is one of the most dynamically developing target area of electronic research and design. According to recent statements of LEDinside, Europe has a leading position with its 23% share in this sector. The most important task of developers - in addition to maximizing the available luminous intensity and efficiency-, is to achieve the longest lifetime with the most reliable design, which requires to take in account external environmental factors that have the strongest and most critical influence to durability. Crucial environmental values like ambient temperature, supply current and voltage should be kept in a certain safety range. This is the reason not to underestimate the necessity of designing in the proper circuit protection.

Transient Surge Threats to Outdoor Devices

It is well know that LED based systems are supposed to have longer lifetime than standard lighting systems, but it is only possible to achieve, if the most critical external influences, such as like LED chip junction temperature, forward current and voltage remains in a safety range. By having longer durability the components are subjected to these environmental issues for a longer period of time, and for economical operations, the maintenance free design is a must. In order to reach the same level of customer trust and satisfaction, than conventional lighting systems enjoy, LED systems should incorporate all kind of safety and protection solutions that make them meeting with requirements of international standards and regulations.

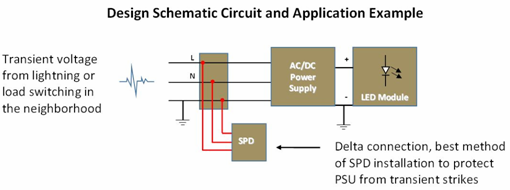

Lightning strikes are travelling electrostatic discharges, usually coming from clouds to the ground with a magnitude of millions of volts. Surges up to thousands of volts are applied to copper wires carrying induced current from lightning strikes occurring up to a few miles away. These indirect strikes usually occur in exposed outdoor wires, transmitting surges to devices like streetlights or traffic lights. The Surge Protection Module, at the upstream of the circuitry, is directly facing surge interference coming from the power line. It diverts or absorbs surge energy, minimizing surge threats to downstream devices like the AC/DC power supply unit in an LED lighting fixture. The initial investment cost and desire for high system reliability are key factors to consider when evaluating the need for installing surge protection devices.

The LED lighting elements are solid state devices and inherently susceptible to early failure due to surge energy. Depending on where the light fixtures are connected to the utility electrical distribution, and depending on the geographical location, they can risk a high degree of failure.

Need of Protection

In the case of streetlights, LEDs are sold on the basis of low maintenance and long life. So designers must ensure that their designs are well protected in order to realize the expected savings. However, one problem for LED lighting installations is protecting against transient overvoltage events. Two major causes of transient overvoltage have long been recognized; system switching transients and transients triggered or excited by lightning discharges (in contrast to direct lightning discharges to the power systems, which are generally destructive and for which economical protection may be difficult to obtain). Median peak currents can range anywhere between 30 to 50kA per strike One particular area of concern is the SMPS front end. Here, the most immediate threat is overvoltage failures. In particular, their pole-mounted outdoor location makes them vulnerable to lighting induced overvoltage's and over currents, two of the most common failure modes at the front end of an SMPS. The other weak point in the lighting circuit is the LED itself. LEDs are fragile solid-state devices, essentially diodes, structured as a P-N junction that emits light when forward biased. The main LED failure mechanisms are mechanical and thermal in nature involving thermal cycles, thermal shock, and LEDs operating at high temperatures causing wire bonds to age and fail. As the metal oxidizes and becomes brittle over time, the likelihood of an LED failure increases. Electrostatic discharge (ESD) events or surges induced by nearby lightning events are another common cause of LED failure.

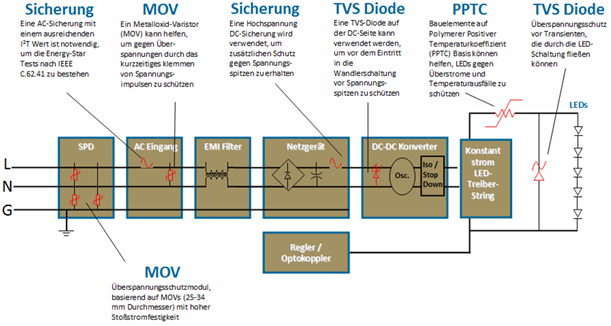

Overview of components designed for circuit protection

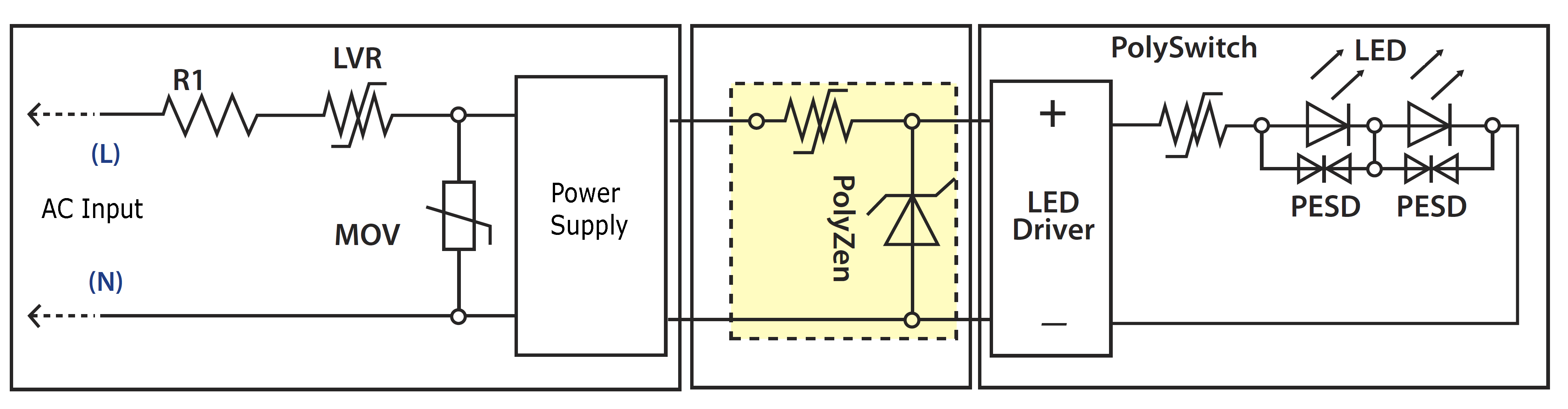

Some of the popular circuit protection solutions target to save the LED chips or the driver components in order to provide maintenance free, long lifetime, others offer protection against negative effects caused by possible malfunction of the luminaire. The white LEDS used in the general lighting applications are usually containing blue chips that are very sensitive for electrostatic discharges, so it is also advised to use ESD protection. There are number of producers include tanning diodes into the LED package, but when it is not applicable, external protection, like parallel PESD devices could be used.

As lifetime of the LED highly depends on the way to take the generated heat off, designers calibrate heat management mainly on self heating. It is however important to take in account the extra heat caused by unexpected environmental issues. It is possible to use a PPTC (Polymer PTC – PolySwitch) device connected in series with the LED chain, which is also advised to connect physically to the heatsink in order to dissipate excess heat. At normal circumstances the PolySwitch, which is a series element in the circuit, has a low resistance that is much less, than the circuit impedance, and hardly has an influence on the performance. As a response of the self heating caused by overcurrent event and/or the external heat, the device trips, its internal structure changes, which increases the resistance quickly and reduces the current of the device to the level that can be safely carried by LED chips. The output of the LED driver can be protected in a similar way from over current caused by malfunction of the electronics itself.

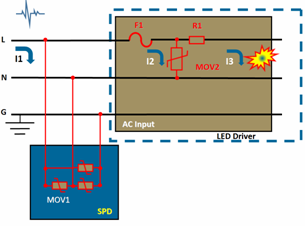

Electric fast transients, like high energy spikes coming from the mains may drastically degrade lifetime of the whole luminaire. To have a useful protection against overvoltage on the input of the LED driver one can use a combination of LVR device and an MOV device. Once voltage spike appears on the input, the MOV starts to activate, delivers the energy to the ground, which increases the current of the LVR quickly, putting it to high impedance state limiting the overcurrent immediately. As seen on the figure the resistor R1 is not there for protection, just to provide further limitation of the current in order to keep it under the level LVR can withstand even in extreme cases. Instead of MOV of course designers can choose silicon based solutions on LED power supply’s AC input, that have no aging effect, that are fully resettable, repetitive devices. Protek devices offer a range of transient voltage suppressor diodes that are designed for 300-440V level, offering ESD protection upto 8/15 kV, EFT protection with surge rating of 1,5kW.

In some cases, LED driver inputs are subject to non-transient overvoltage events, that are caused by accidentally connected higher than nominal voltage or reverse polarity power supply. An example can be a LED based table lamp, which should be energized with an external power supply, and a wrong device is used. In these cases a semiconductor based fast clamping device should be used for protection, like the PolyZen device of TE Circuit protection (now Littelfuse). PolyZen is designed as a combination of Zener diode provided overvoltage protection and a PolySwitch device for current limiting in closed thermal coupling. The PolySwitch device will protect the Zener diode from overheating and burning down, by providing effective current limiting once the Zener is activated and its current grows.

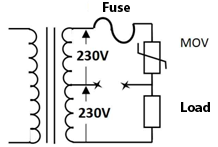

As mentioned above, the overvoltage events caused by transients and spikes of the line voltage, could be effectively handled by using metal oxide varistors (MOV) in LED based lighting devices. Over voltage protection devices are not only subjected to short transients, but sometimes they need to handle long abnormal overvoltage of minutes or hours, in case of faulty mains network or transformer’s neutral cable loss as seen on figure.

In these cases the voltage of the MOV grows above its nominal voltage, an due to the current limiting of the impedance of the load, the fuse may not blow, causing all excess energy concentrated to on the MOV, which may cause burning and destroying it.

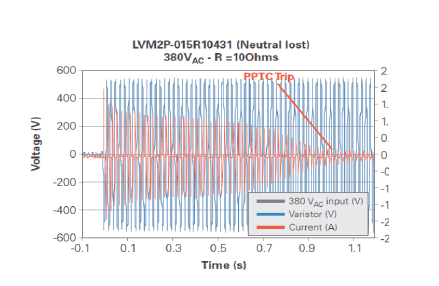

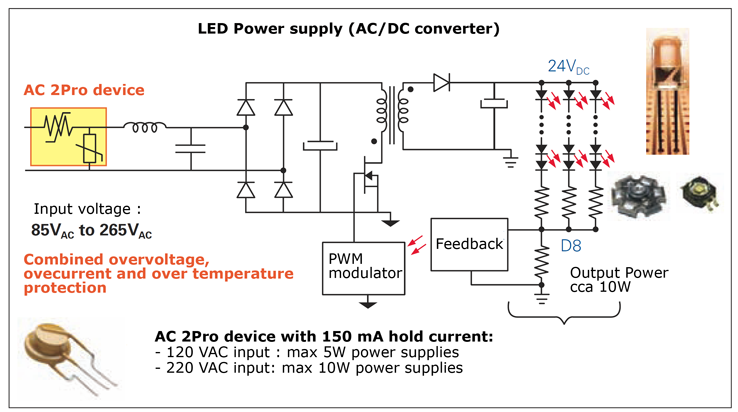

Lightning strike, sudden switching of huge inductive or capacitive load, neutral cable loss can induct such high transient voltages, which cannot be handled by the varistor, the device would suffer from thermal runaway, can blow or burn. Recently there are hybrid devices appearing on the market, which incorporate effective overtemperature protection to the clamping overvoltage device. These devices could be used - among others - for input protection of power supplies of LED based lighting systems. During normal circumstances, the voltage appearing on the MOV does not exceed the maximum permitted voltage of the device, and even the extra energy generated by handling the fast overvoltage events caused by e.g. spikes, will also be handled. The abnormal cases, like for instance the neutral cable loss will result however long transient overvoltage events, and without effective overtemperature protection, the MOV would suffer from thermal runaway. Usual solution was using a serial TCO, and an extra overcurrent protection element, like a fuse in order to limit the generated transient overcurrent. Instead of using discrete circuit elements, it is better to use an integrated solution. TE Circuit Protection’s (now Littelfuse’s) AC2PRO devices offer this kind of hybrid protection, being a combination of a metal oxide varistor and a thermally coupled PPTC device. During abnormal operation, the MOV goes to low resistance state and starts to conduct current to the ground, that can grow fast to a value, which would lead to thermal runaway, burning down the MOV and result fire. The integrated PPTC however would also warm up partly because the thermal coupling with the hot MOV, partly because the I2R self heating of the growing current. This warming up will activate the current limiting ability of the PolySwitch, which then would go into high resistance state and save the MOV from burning down. A further advantage of the device is its reset ability, when the problem is gone, after a certain cooling time, the AC2PRO resets to normal state and is ready to function normally. Maintenance costs could be minimized as no replacement is needed. The figure shows the operation of the AC2PRO device during a transient event caused by neutral loss. The AC2PRO is available at the moment in 150 mA, 350 mA and 700 mA hold current versions, with 400V MOV nominal voltage.

Suggested locations of overvoltage protection components

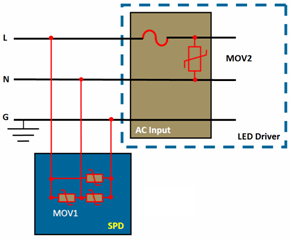

To protect LED lights as good as possible, it is reasonable to use a protection module that protects in the best way against surges. To achieve this goal, the best way is to use a delta connection.

It is also very important to provide the best location for the MOVs, the bigger size varistor of these surge protection modules should be triggered faster than the smaller varistor inside the LED driver. Therefore its breakdown voltage should be less than the one in the driver, as

large part of the energy should be handled in the larger size MOV and the smaller size MOV should only be subjected to the remaining part that it can still handle.

The summary of rules applicable for the installation are:

- The main part of the transient energy should be handled by the larger MOV1

- The selection rule for maximum continuously allowable working voltage (Vm) is: Vm(MOV1) <= Vm(MOV2)

- Maximal clamping voltage (Vc) selection rule is : Vc(MOV1) <= Vc(MOV2)

- It may be a good solution to use a serial connected inductor in combination with the SPD , that MOV1 can handle higher surge energy : V(MOV1) = V(MOV2)*dI/dt

Even in case of keeping these rules and huge part of excess energy is handled by the SPD, LED driver’s input will still be stressed by overvoltage that may cause malfunction or damage. Due to this fact a local protection should cooperate with the SPD. The remaining part of the fast transient overvoltage should be handled by a fast and low clamping voltage MOV device. The clamping voltage on MOV2 should be kept above MOV1’s one in order to maximize I1, and reduce I2 over current, which will make sure that the remaining transient current will not blow the F1 fuse. Possibly enlarging the total resistance of the primary circuit (NTC, EMI filter, NTC, rectifier bridge, PFC module, transformer, transistor) I3 current may be minimized, the risk of LED component damage is reduced. To protect the components sensitive for excess voltage remained after the SPD protection started, we can use fast TVS diodes.

PROTEK SPD modules with extreme surge handling possibilities for LED lighting fixtures

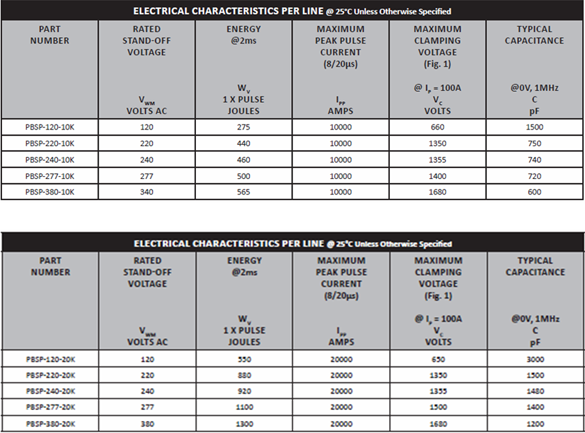

The new overvoltage protection modules of PBSP series of the manufacturer ProTek Devices are protection modules, which are designed to protect against lightning surge currents up to 10000 ampere (PBSP-XXX-10K series) or up to 20000 ampere (PBSP-XXX-20K series). This means the ability of energy absorbing of 2500/5000 W (10/20 kA Peak Pulse Power @ 8/20μs) between phase – neutral, phase-ground and neutral- ground cables. The modules are available in different nominal voltage versions. The under UL1449 type 4 recognized modules meet the ANSI Standard C136.2 / IEEE C62.41.2 Location Category C High Exposure and are IEC61643-11 Class II / EN61643-11 type 2 compliant. In addition to the compact form factor with mounting tabs, the modules are made of non-flammable plastic case and being waterproof and dustproof according IP66.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2015/4 | Elektronet : elektronikai informatikai szakfolyóirat, 2015. (24. évf.) 4. sz. 22-24. old. |

| 2 | Elektronet online | Kül- és beltéri LED-világítások túlfeszültség-védelme |

| 3 | Hungarian version | LED világítások túlfeszültségvédelme |

| 4 | TechStory M2M | Kül- és beltéri LED világítások túlfeszültség-védelme |