Tobias Jung, Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Development of ABC coil families – the new QS series for automotive industry

09 November 2015

Summary :

The arising demand for SMD power inductors is mostly driven by requests arising consumer applications like camera, mobile phone, notebook PCs, however standard industrial applications have also special requirements, that has to be fulfilled. To design quality equipments engineers must use quality components, so very important measures in case of inductors are the maximum power can be concentrated into the given volume, the high saturation current, and in order to keep losses minimized and efficiency high, the low DC resistance of the coil. In addition to the technical properties also the economical issues has to be considered, like the production costs, that are continueously increasing in China due to the fact the hand made parts involve more and more human resources, while wages are increasing. This trend affecs all manufacturers, who does not have fully automated production. This paper is about to introduce the various technological steps done by leading taiwanese manufacturer of inductors ABC to answer challenges of today’s trends.

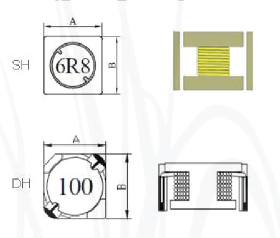

Shielded and unshielded SMD power inductors SH→DH

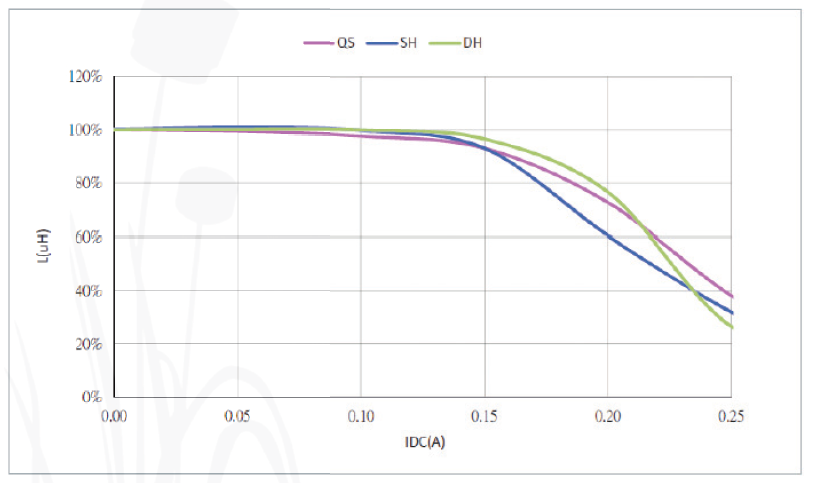

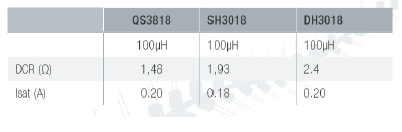

The magnetic field generated by the shielded inductor stays within the component, and the emitting of magnetic disturbances outside the package will remain minimal. In the unshielded inductor some of the magnetic flux is radiated outside, therefore the risk of coupling to other subsystems and components is higher. Using shielded inductors give some more advantages, as the complete magnetic flux remains inside the component, the power efficiency is higher, less wire turns are required to achieve the same inductance. However the inductance change vs current curve drops earlier because of the saturation characteristics, so the unshielded power inductor is easier to work with larger current.

A very popular item in the European market this the classic square type flat SMD power inductor. These items are widely used in all kinds of applications. The construction is optimal for low profile which is required in many “Asian products" like camera, HDD, notebook, etc. It can be produced at low cost that involve mainly manual work. Due to manual placing of center pole into outside shielding core, the air gap cannot be controlled very well. The standard tolerance for L and DCR is typically +/- 30%. However, the industrial market requires more precise components. Also, "European products" normally don't require low profile. A cubic housing would be more efficient. ABC is continuously developing new parts to contribute to this trend.

To solve the issue about wide tolerances, ABC developed the DH type, which is pad compatible with the SH type. This construction has two major advantages. The center pole with winding is auto-placed and centered into the RI core (shielding core). This enables the manufacturer to control the air gap very well. The typical tolerances for L and DCR are controlled at +/-20% (from 1 0`H and higher).

The second advantage is the top down orientation of the lead wire. Other than with SH type, the end of the wires are guided to solder pad from top of the inductor. This can avoid soldering problems.

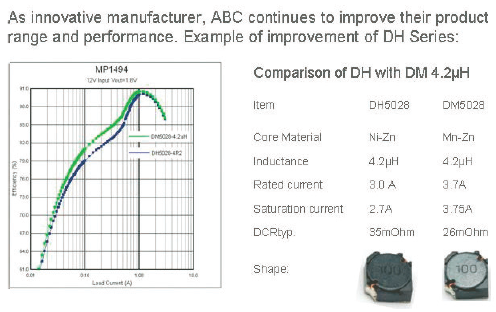

Energy storage in DC/DC converter DH→DM series

SMD power inductors are also used in DC/DC converters for energy storage purposes. There are buck (step-down), boost (step-up), and buck-boost converters which convert the DC input voltage from high to low or low to high in order to provide the DC power to various circuits in a system. In order to contribute to a higher efficiency of DC/DC converter, ABC developed the DM family of inductors, which are pad compatible with the SH and DH families. This item uses Mn-Zn as core material [before: Ni-Zn] and Ni-Zn for the shielding core. Due to the different material performances, the DM type have much lower core losses. The saturation current is typically 25% higher and the DCR 25% lower compared with DH type.

The figure shows the efficiency of DCDC converter MP1 494 of MPS compared when using DH and DM type inductor as output choke. The next step for ABC is to develop DM – style parts with a cubic housing in order to have more performance based on the same AxB dimensions. This development targets 1 00% the European market, where a high performance, high accuracy is needed and the low profile is not the major driver of electronics development. According to the roadmap these parts might be available from Q4/2013. The idea is to make 4x4x4mm/ 5x5x5mm / 10x10x5mm parts.

In general inductors to be used in DC/DC converter applications must satisfy the below requirements:

- High rated currents: saturation current must be high enough for the inductor to keep operating in the linear range.

- Low DC resistance: important for high efficiency of the converter.

- Low losses at high frequencies: important for high efficiency and low heating of the converter.

- SMD housing: keep costs low for mass production.

Quality and price DH/SH→QS

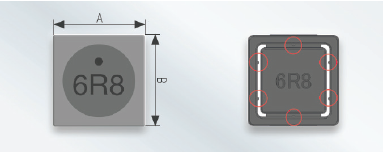

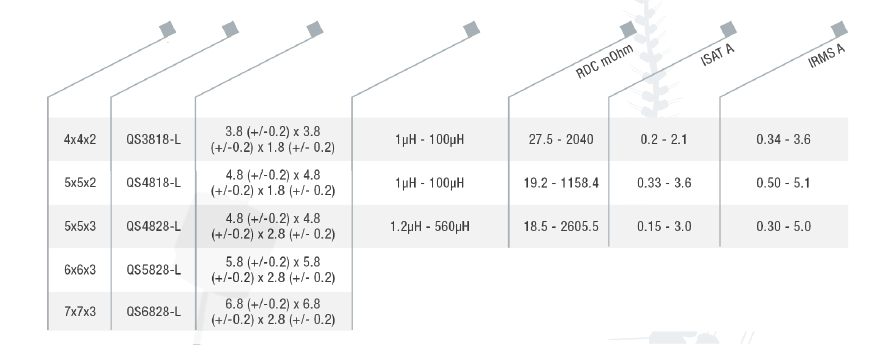

The new QS series is ABC’s new shielded SMD power inductor family, that is available in medium sizes (4×4 mm ~ 5×5 mm, soon in 7×7 mm). It has been developed especially for automated production in order to reduce costs. The special construction with positioning knobs helps to increase production yield and further adds to reducing cost. By using PVD instead of plating for metallization, QS type is produced in a eco-friendly, energysaving way.

In order to reach an even distribution of inductance values during manufacturing process, it is necessary to control the air gap between DR core and shielding core precisely. The original design was changed from round shape to square shape. Positioning knobs in the shielding core are used to support exact alignment of cores and keep distance same all around. Besides the better production yield, this technique also enables ABC to specify their QS type coils with tighter tolerances compared to older design. For QS type, PVD (physical vapor deposition) is used to form the electrodes. The advantages are a very even and smooth surface and this method is considered eco-friendly compared with electro-plating because no chemical solvents are used.

Crescent PCB pattern is very popular at manufactures of mid sized inductors. This way of metallization is quite simple (for manual process – by dipping) and will give the coil a good solder connection on the PCB. By using PVD, ABC decided to change the PCB pattern from crescent shape to the square shape.

Positive: easier for new design – compatible with crescent design (with limiation).

Mostly it can be shown that there is a slight performance improvement for QS type. As documented on below figures, the inductance tolerance can be narrowed down to +/- 20% (SH +/- 30%) and the saturation curve has an approx. 10% increased performance at higher currents.

QS coils are developed to solve all the problems that prior versions brough from technological point of view such as soldering, processability, manufacturing risk, etc and are meant to replace the older versions e.g. ABC‘ s popular SH-; DH- or SU type that suffer from continuously cost increase due to most of their production processes being manual work.

QS coils are suitable for easy pick and place, excellent soldering up to 260°C as well as RoHS and Reach compliant.

Due to automatic production process the quality will become very stable. On top of this, ABC uses auto soldering, auto marking, auto glueing and auto test & packaging.

ABC set their quality goals high and add a double 1 00% outgoing inspection (manual and automatic) to their process. Parts are in top condition and passed successfully the AEC-Q200 tests and are therefore suggested to use in automotive applications.

Further development on QS family

ABC continues to develop new productions towards to the three directions high speed, high current, low profile. One example are coils with powder injection or amorphous core material. Regarding QS type the following items are under development to complete QS line up:

- QS3828 (3.8×3.8×2.8mm),

- QS5828 (5.8×5.8×2.8mm),

- QS6828 (6.8×6.8×2.8mm).

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2015/7 | Elektronet : elektronikai informatikai szakfolyóirat, 2015. (24. évf.) 7. sz. 24-26. old. |

| 2 | Elektronet online | ABC-induktivitáscsaládok fejlődése, az új QS-sorozat az autóipar számára |

| 3 | Hungarian version | ABC induktivitás családok fejlődése az új QS sorozat az autóipar számára |